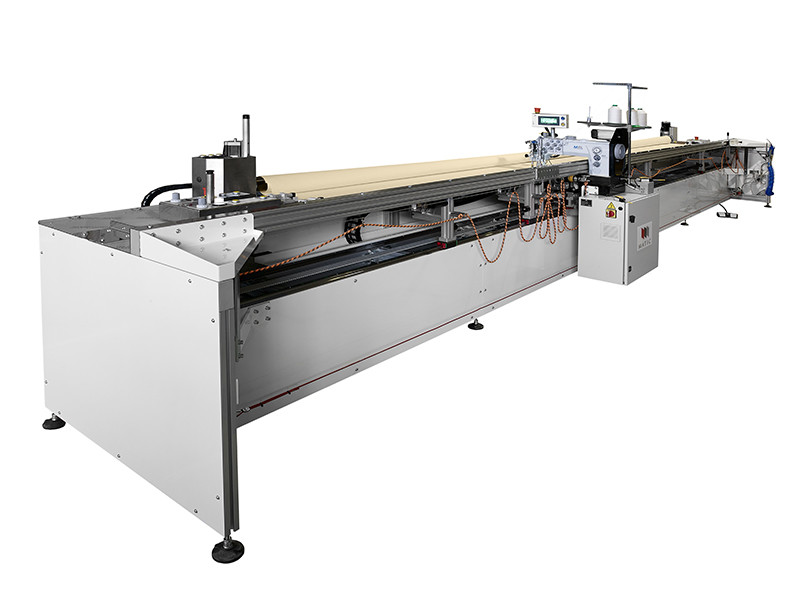

Automatic linear sewing machine with travelling head for joining and hems.

Hercules is an industrial sewing unit specifically designed for the awning industry. It is the perfect solution for manufacturers who need high quality and fast performance for sewing awning fabrics (acrylic, polyester, technical textiles, PVC, etc). It is equipped with a travelling sewing head that moves along the length of the fabric.

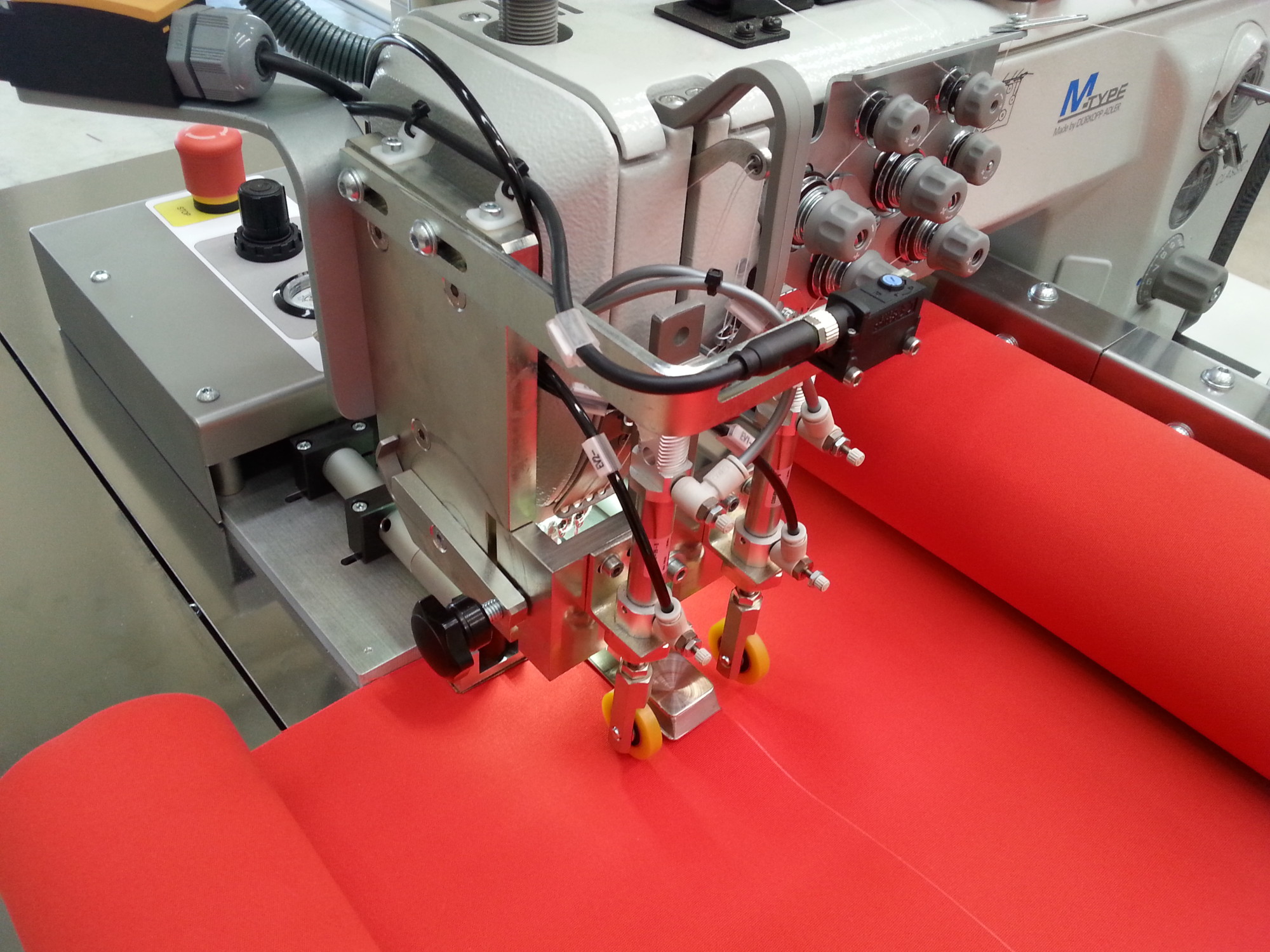

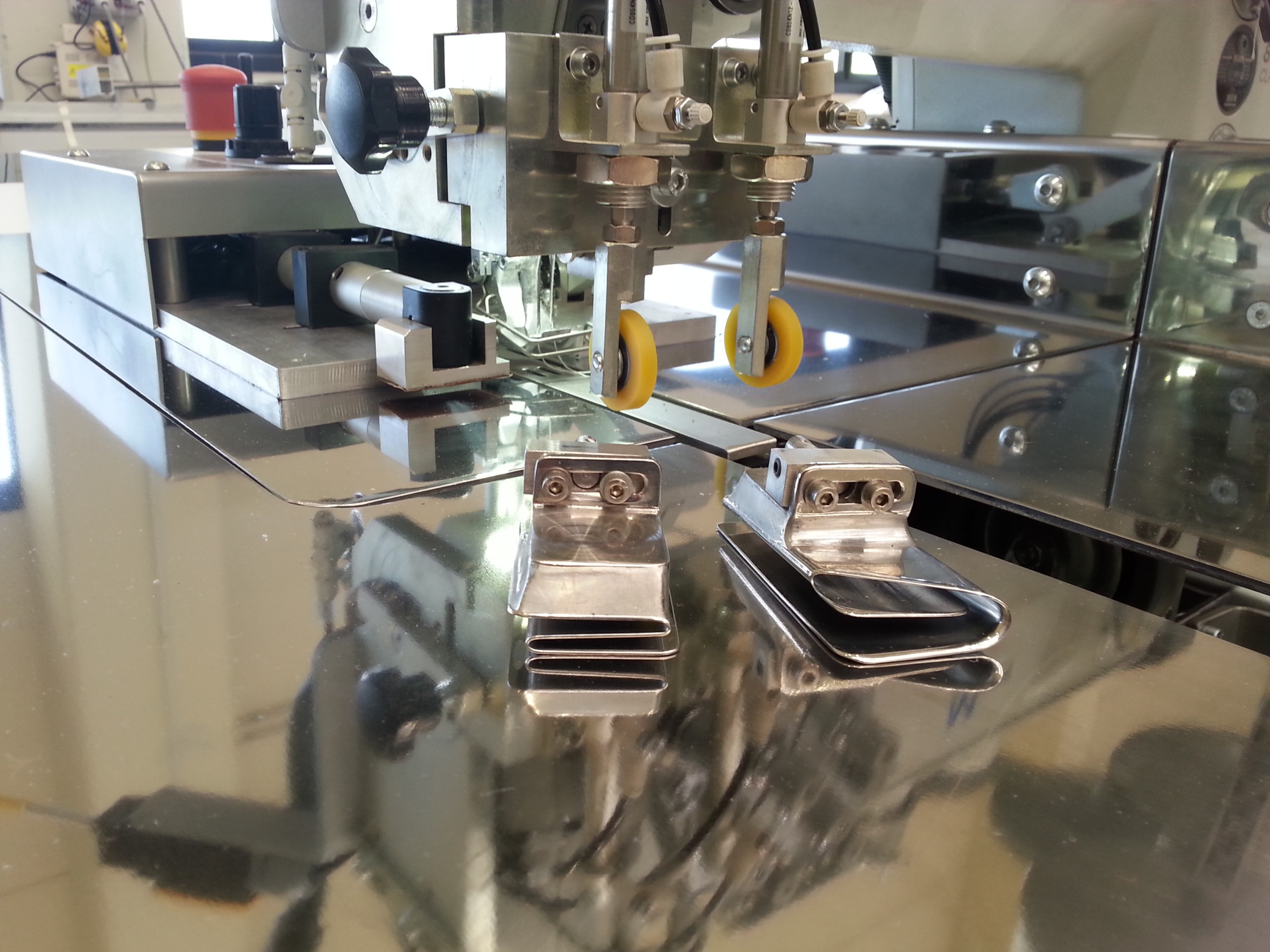

Hercules allows you to work with any sizes of fabrics, even if they are cumbersome. The fabric is held in place and tensionned with the use of clamps to ensure straight seams every time. With our special guides, it is possible to do lateral hems, overlaps, reinforcements and insert a PVC and/or pergola core.

Software is installed for remote control and support through an internet connection.

The Industry 4.0 kit is an optional feature that can provide production traceability and data reporting.

Hercules allows you to work with any sizes of fabrics, even if they are cumbersome. The fabric is held in place and tensionned with the use of clamps to ensure straight seams every time. With our special guides, it is possible to do lateral hems, overlaps, reinforcements and insert a PVC and/or pergola core.

Software is installed for remote control and support through an internet connection.

The Industry 4.0 kit is an optional feature that can provide production traceability and data reporting.

- Useful sewing length: 5.6m up to 14m** (18ft to 46ft)***

- Machine length: 7.2m up to 15.6m** (23ft to 51ft)***

- Operation mode: automatic, semi-automatic and manual

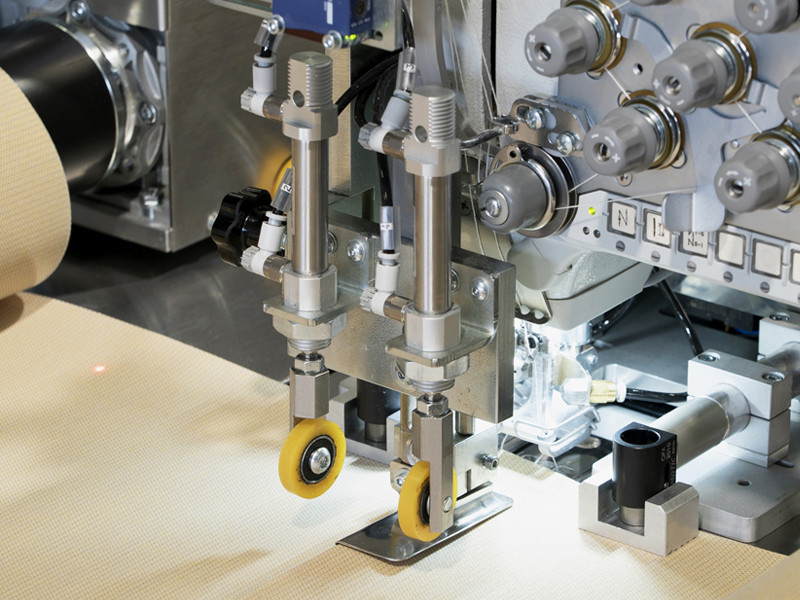

- Latest generation Dürkopp Adler cl 867 sewing head

- Electrical voltage EU: 230C / 50 Hz AC US: 230V/ 60Hz AC

- Air pressure: 6 bar

- Complies with CE safety regulations

*** Precise measures are given in metric system. Imperial values serve as a reference.

- Automatic sewing machine with travelling head

- Industrial sewing for acrylics, polyesters, PVC and technical textiles

- Applications: overlaps, lateral hems, reinforcement, PVC and/or pergola core insert

- Straight and perfect seams - 3+3 pneumatic transport clamps in front and back to provide continuous tension during the sewing process

- Includes automatic devices: thread cutter, foot lifter, back-tack, lubrication, remaining bobbin thread control*

- Machine controlled by PLC with digital display

- 7” colour touch screen control panel

- Remote control and support via Wi-Fi or LAN connection

- Sensor to detect the end of the fabric with automatic return of the head

- Needle cooling*

- Thread break sensor*

- Statistic records of sewing process*

- Illumination of the sewing area by LED

- Industry 4.0 kit*

- QR code reader*

- Production Traceability and data reporting*

- Built for high production capacity - High sewing speed

- Takes less space than a travelling tray linear sewing machine

- Straight and perfect seams - 3+3 pneumatic transport clamps

- Accurate machine with high quality results

- Dürkopp Adler cl 867 sewing head with high capacity hook (increase capacity by 70%)

- Customized guides for different applications - based on the customer's needs

- Guides are easy and fast to change

- Ergonomic 7” colour touch screen with adjustable positions according to the operator's posture.

- Designed to be operated by one low-skilled operator

- Low cost of maintenance and operation

- Remote control and support via Wi-Fi or LAN connection