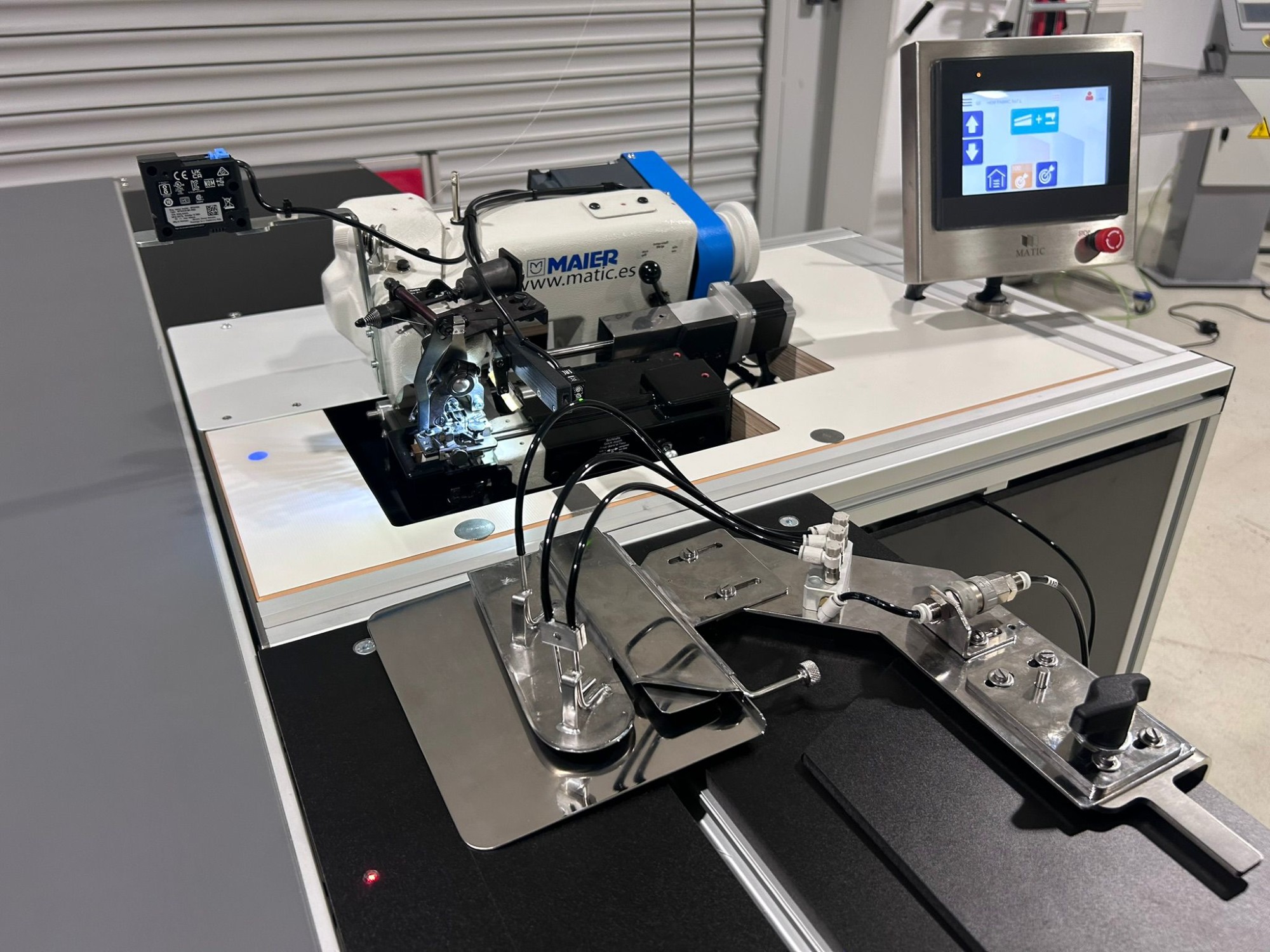

Automatic sewing machine with conveyor belt for bottom and side hem on curtains.

The Nyx Compact Blind Stitch sewing system with automatic conveyor belt is a solution for the sewing of bottom and side hems on traditional curtains.

It is easy to use and fast, reduces production time and increases the output, with a non-skilled operator.

The result will be high quality tension free flat seams for bottom and lateral hems. The guides are custom made for each finishing application and will adapt the machine to your usual production.

Software is installed for you to have remote control of operations, and get remote support from Matic.

With the optional Industry 4.0 kit, the sewing program and settings will be loaded automatically by reading the QR code of the work piece, and you can easily achieve production traceability.

It is easy to use and fast, reduces production time and increases the output, with a non-skilled operator.

The result will be high quality tension free flat seams for bottom and lateral hems. The guides are custom made for each finishing application and will adapt the machine to your usual production.

Software is installed for you to have remote control of operations, and get remote support from Matic.

With the optional Industry 4.0 kit, the sewing program and settings will be loaded automatically by reading the QR code of the work piece, and you can easily achieve production traceability.

- One needle sewing head

- Conveyor belt synchronized with the sewing speed

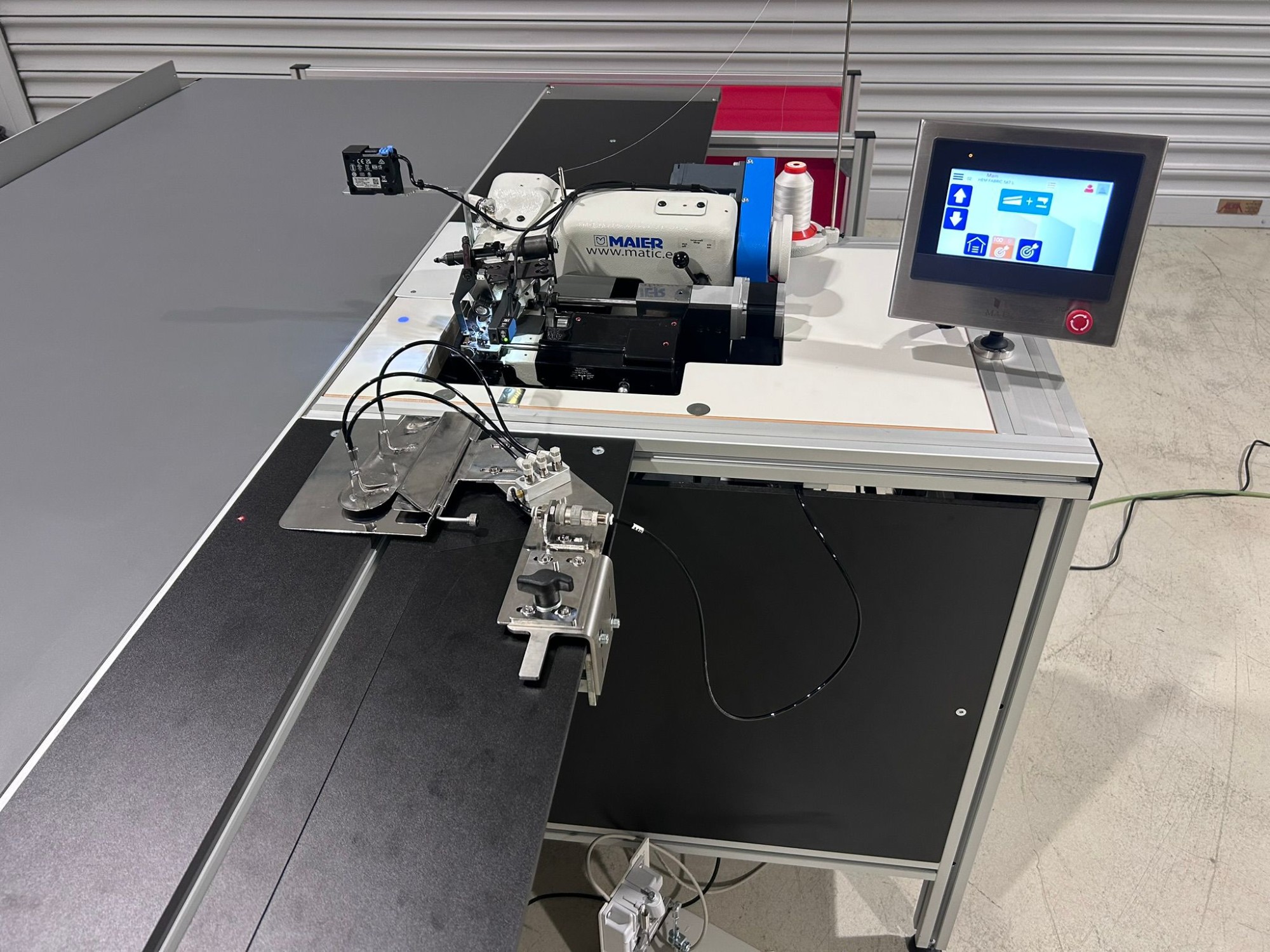

- Conveyor belt length 2380 mm (94")**

- Conveyor belt width 800mm (31.5")**

- Operation mode: manual, semi-automatic

- Electrical voltage (EU/US) 220V F+N // 50-60Hz

- Air pressure 5-6 bar

- Our machines comply with all CE safety rules

- Quick change for the several sewing guides – no tools required

- Pneumatic guides to ease the fabric hemming and to hide the threads

- Automatic return of the sewn material

- Additional pedal to use conveyor belt independently from the sewing process.

- Tilt table to adapt with an auxiliary table

- Rear driven roller to ease the guiding and feeding of heavy fabrics

- Fabric box for collecting the sewn materials

- Maintenance notice

- Remote support via Internet, Wi-Fi or LAN connection

- Industry 4.0 kit*

- Production Traceability and data reporting

*Optional

- Great solution for a small area. The size is only 4m2 (43 sq.ft), which is easy to place in any location.

- High productivity and constant quality, thanks to the ergonomic design of the work station in a stand-up position for the operator.

- The pneumatic guides are custom made for each application – will be adapted to the production requirements, quick change of the guides.

- Automatic return of the fabric on the conveyor belt when the sewing process is finished : faster production, less participation of the operator.

- The conveyor belt synchronizes with the speed of the sewing machin and is adjusted for light and heavy fabrics.

- Fast and easy change of applications at the touch screen control panel.

- Ergonomic 7” colour touch screen with adjustable positions according to the operator's posture.

- Remote support: Matic engineers can connect to the machine remotely to resolve software incidents or production incidents

- Remote access to the software through Wi-Fi or LAN connection, for programming, production data etc.

- Optional Industry 4.0 kit:

QR code also contains information on the program and settings that must be used to sew the application: thread tension etc. - avoiding errors and / or quality problems.

ADVANTAGES

- Great solution for a small space.

- No need a skilled operator.

- Increased production and constant quality.

- Custom guides, easy to change.

- Conveyor belt speed synchronized.

- 7” color touch screen control.

- Remote control and remote support.

- Optional Industry 4.0 kit.

Products

SEWING

Industries

CURTAINS