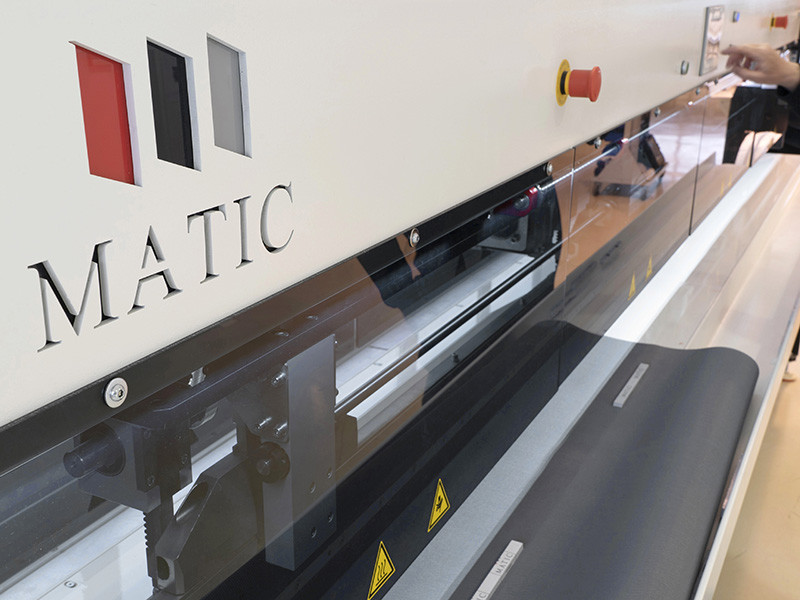

THE NEW GENERATION OF ECO-FRIENDLY IMPULSE WELDING MACHINES. It is a completely original and ground-breaking welding system compared to traditional impulse welding machines.

PERSEO is a completely original and ground-breaking welding system compared to traditional welding machines.

It is eco-friendly, no need for an air compressor, which means a significant saving in electricity.

The electronically controlled movement provides the highest precision for pocket sizes and overlaps on a variety of different fabric types.

It is eco-friendly, no need for an air compressor, which means a significant saving in electricity.

The electronically controlled movement provides the highest precision for pocket sizes and overlaps on a variety of different fabric types.

- Useful welding length of 4 or 6 meters.

- 6, 10, 20, 25mm electrode.

- 100 programs for different jobs.

- 40 groups of programs to automate operations and work in sequence.

- Motorized movement of the upper welding bar.

- Intermediate stops and controlled lowering of the electrode for special jobs.

- Adjustable electrode pressure on the touch screen. (ability to weld with different pressures)

- Colour touch screen.

- Temperature regulator

- Welding and cooling time control

- Panel joining with automatic stops position.

- Reinforcement welds with automatic stop position.

- Electronic offsets of the movements for union, pockets, reinforcement ...

- Automatic pockets *

- Guide to weld Zippers, Profiles ... *

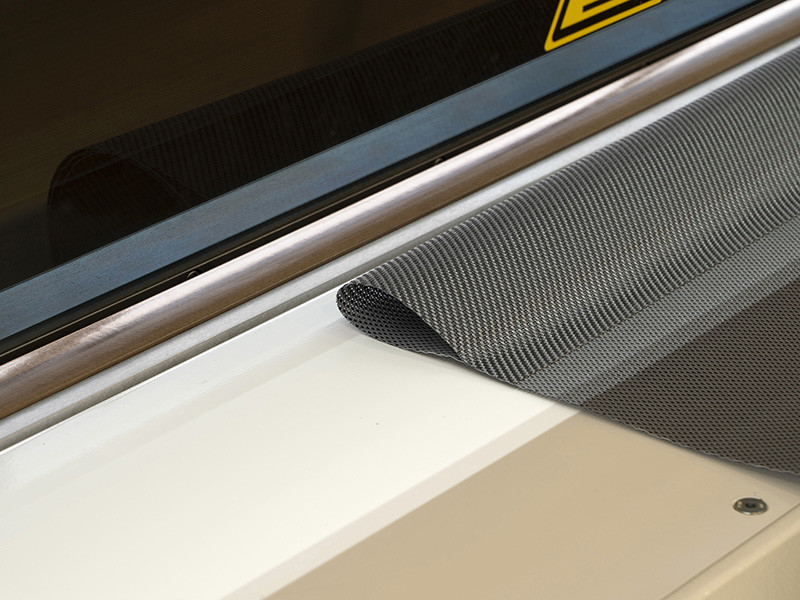

- Invisible welding (patented by Matic, patent number: 9,096,015)

- Programs for different applications and fabrics

- Programs to automate operations and work in sequence.

- Remote LAN / Wi-Fi connection for after-sales service

- Industry 4.0 control and traceability of production. *

- Work area with led lighting *

- FIXMATIC tape roll holder for welding PVC-free fabrics *

- Front and rear tray prepared for heavy fabrics.

- Adjustable in height.

- Machine open on both sides.

- 400/220 THREE PHASE

- No need for an air compressor.

- Low energy consumption

- Easy to use for anyone, no special skills required.

- Low cost of operation and maintenance.

- The “Seamless” Technology, (patented by Matic, patent number: 9,096,015), will produce invisible welds. The material will not become shiny or glossy when welded, which will give your products a more pleasant and high-quality appearance.

- It will not interfere with other equipment in proximity.

- Does not produce Sparks, very safe machine for the operator.

- Achieve good finishes on a wide variety of fabrics.

- Manual or automatic* folder for making pockets.

- Ideal solution to produce a great variety of different products and different fabrics with the same machine: Awnings, roller blinds, PVC and / or textile banners, exterior screens, curtains, etc.

- Guide and tools to facilitate the welding of different thermo-weldable profiles, can be customized.

- Open sides to weld larger materials by welding multiple times

ADVANTAGES

- Eco-friendly: No compressed air needed, low energy consumption.

- Industry 4.0, remote screen operations, remote support.

- Save energy, save installation and maintenance work.

- Ergonomic: Easy to reach all the working areas.

- Affordable with all-around functions.

- High precision for pocket sizes and overlaps.

Products

WELDING

Industries

ROLLER BLINDS / ROLLER SHADES

AWNINGS

EXTERIOR SCREENS

PERGOLA

DIGITAL PRINTING