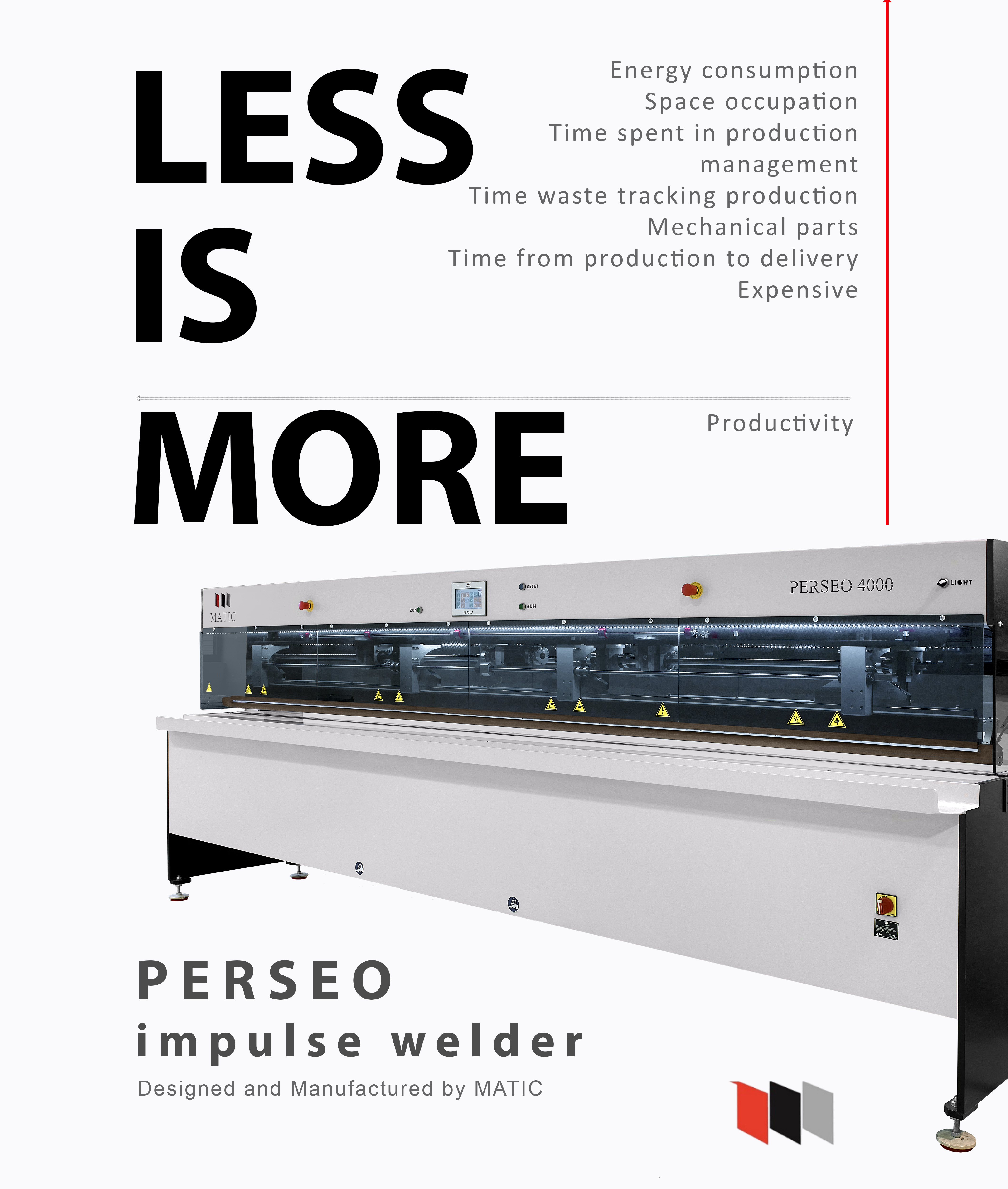

At Matic, we keep in mind that “less is more” when we design and manufacture our machines. We want our customers to achieve MORE productivity by having LESS of the troubles mentioned above. We make good on our promise by ensuring that:

- LESS fabric is wasted

- LESS operators are needed

- LESS skills are needed for operators

- LESS space is needed for the production process

- LESS time is needed from production to delivery

…

In this series, we would like to share what Matic is concretely doing with our products and services and how we apply the “less is more” concept to help customer achieve more with less.

In this first blog we will talk about our new impulse welding machine PERSEO.

The Designing and Manufacturing of a New Machine

PERSEO is a ground-breaking welding system compared to traditional impulse welding machines. Our design engineer, software engineer, production and sales team have worked together to create this machine which has been well accepted by the market after its launch this April.

Check how many words of ¨LESS¨ you can find in the following description of PERSEO:

Production/quality supervisors can operate or supervise the screen from their computers and modify sensible parameters from the welding recipes (welding temperature, time...) without having to be at the machine in the production area.

This allows your company to easily and quickly identify when, where, by whom, and how a product was produced. In the event of production failures, the cause of the error can be determined quickly. This way, further errors can be prevented, product and process quality as well as efficiency will be increased, and costs will be reduced. Gathering production data can also help you identify excellent employees and have them cross-train other colleagues.

If you are also fascinated by ¨LESS IS MORE¨ idea, please check the videos of PERSEO to see how it works to weld awning, blinds, zip-screens, and banners.

Or contact us to get your samples welded by PERSEO.

Stay tuned for the next blog in the ¨LESS IS MORE¨ series.

- LESS fabric is wasted

- LESS operators are needed

- LESS skills are needed for operators

- LESS space is needed for the production process

- LESS time is needed from production to delivery

…

In this series, we would like to share what Matic is concretely doing with our products and services and how we apply the “less is more” concept to help customer achieve more with less.

In this first blog we will talk about our new impulse welding machine PERSEO.

The Designing and Manufacturing of a New Machine

PERSEO is a ground-breaking welding system compared to traditional impulse welding machines. Our design engineer, software engineer, production and sales team have worked together to create this machine which has been well accepted by the market after its launch this April.

Check how many words of ¨LESS¨ you can find in the following description of PERSEO:

- Modular design takes less time to be produced, and easier to be updated.

- Creative design uses less mechanical parts (40% less), this saves time spent on installation and maintenance.

- Compact design not only makes it more ergonomic, so the operator can reach all the working area easily, but also makes it occupy less space.

- Less energy consumption since no compressed air is needed.

- Less involvement from managers on the production floor thanks to Industry 4.0 functions like remote support and remote operation of the machine.

Production/quality supervisors can operate or supervise the screen from their computers and modify sensible parameters from the welding recipes (welding temperature, time...) without having to be at the machine in the production area.

- Less time spent in tracking production for quality management

This allows your company to easily and quickly identify when, where, by whom, and how a product was produced. In the event of production failures, the cause of the error can be determined quickly. This way, further errors can be prevented, product and process quality as well as efficiency will be increased, and costs will be reduced. Gathering production data can also help you identify excellent employees and have them cross-train other colleagues.

- Less machines are needed.

- We have successfully proven that by applying the “less is more” mentality we have made the PERSEO a less expensive machine without compromising on any functions.

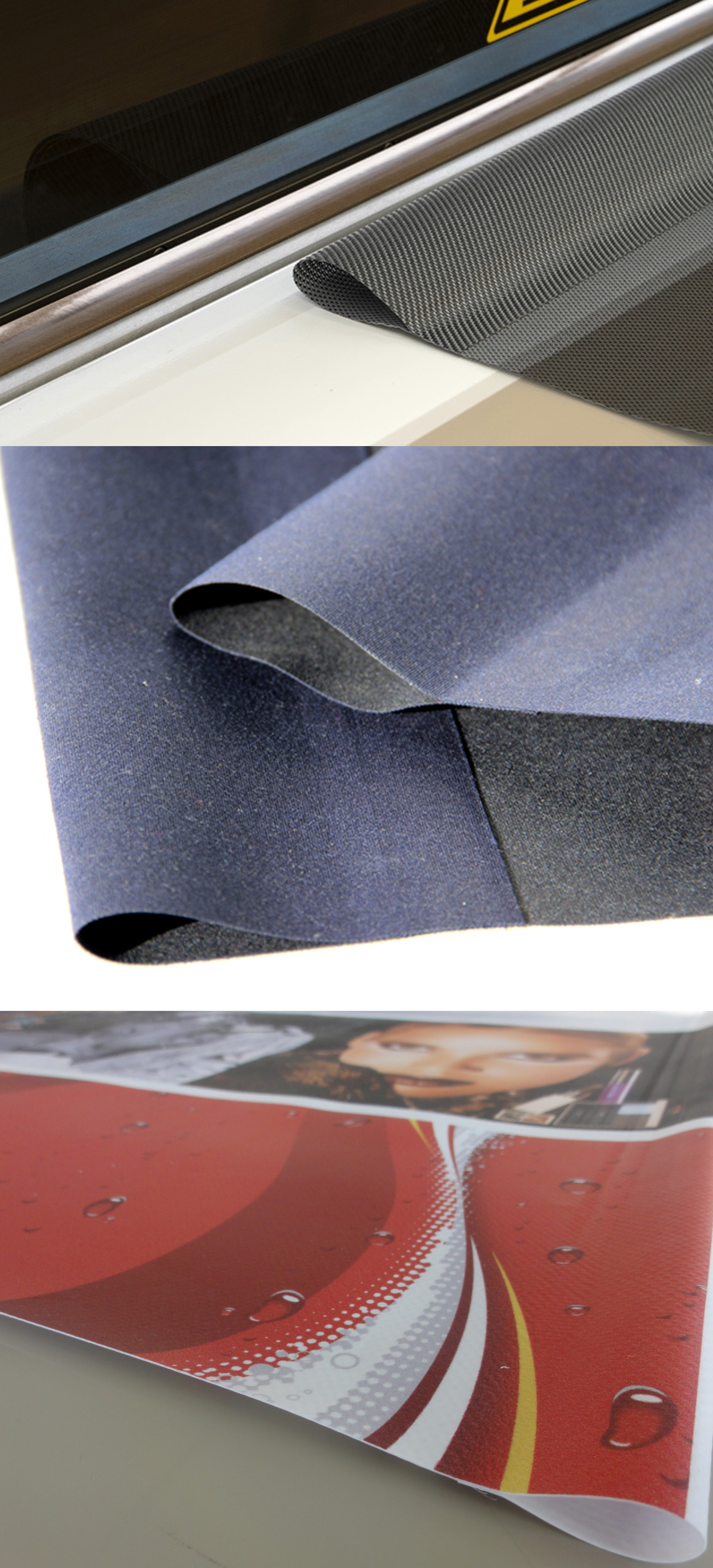

If you are also fascinated by ¨LESS IS MORE¨ idea, please check the videos of PERSEO to see how it works to weld awning, blinds, zip-screens, and banners.

Or contact us to get your samples welded by PERSEO.

Stay tuned for the next blog in the ¨LESS IS MORE¨ series.