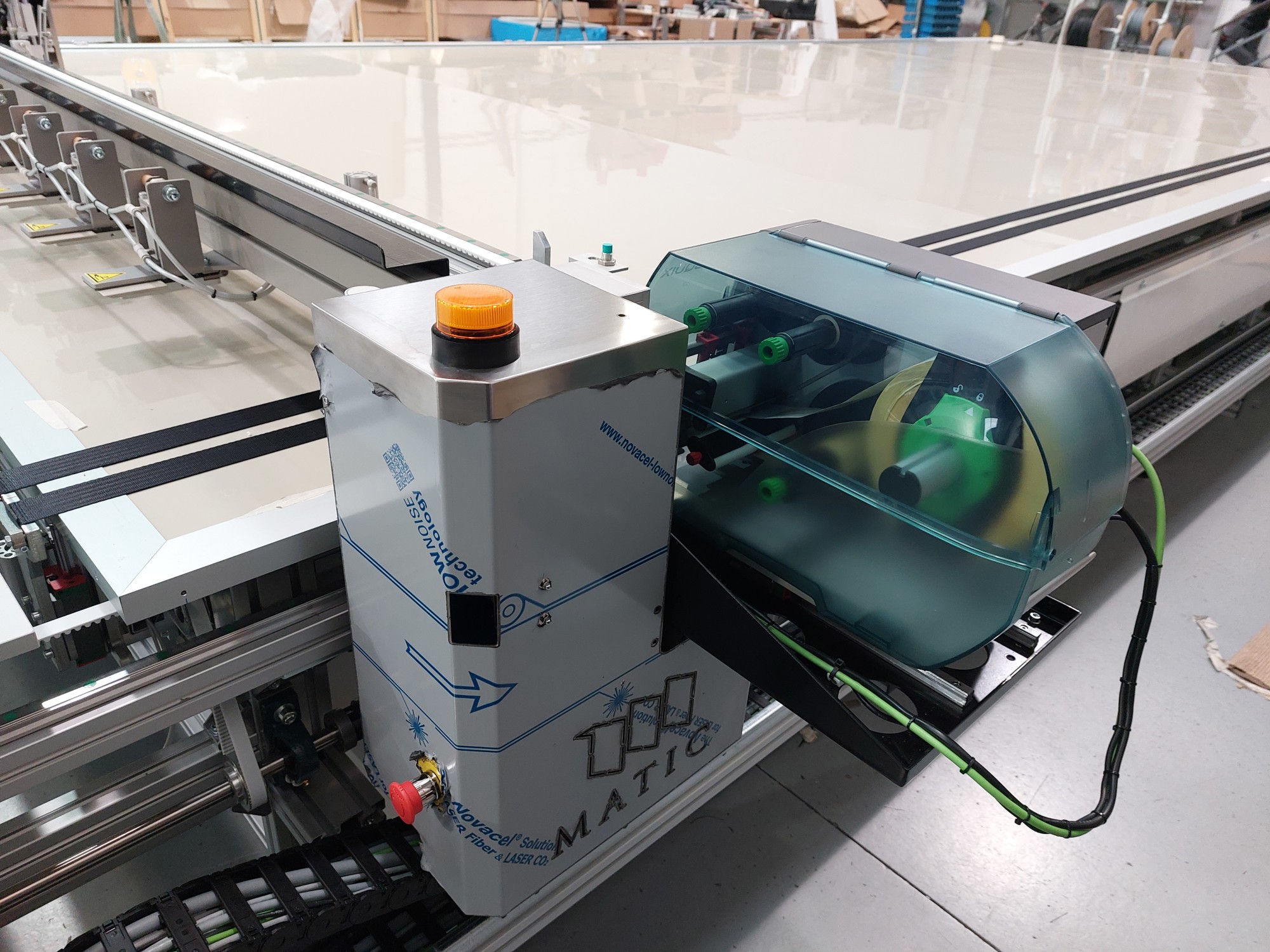

X-Y Cutting Machine with Two Rotating Pressure Blades and Dual Fabric Holding System.

Productivity and Precision

The M1 line of cutting machines offers the perfect blend of speed and precision. Variable cutting speeds provide optimal results by adapting to different types of fabrics. The two pressure bars eliminate any fabric movement during the cutting process. Its design, construction, and user-friendly features have made the Matic M1 series one of the best-selling machines on the market.

The M1 Plus machine is an automatic cutting table that cuts all four sides, eliminating the need to rotate and manipulate the fabric during the cutting process.

It incorporates two different pressure systems, one for the X-axis and another for the Y-axis, to keep the fabric stable during the cutting process in both directions.

Built and designed for efficient production of roller blinds, awnings, panels, vertical blinds, Roman shades, mosquito nets, and samples.

The M1 line of cutting machines offers the perfect blend of speed and precision. Variable cutting speeds provide optimal results by adapting to different types of fabrics. The two pressure bars eliminate any fabric movement during the cutting process. Its design, construction, and user-friendly features have made the Matic M1 series one of the best-selling machines on the market.

The M1 Plus machine is an automatic cutting table that cuts all four sides, eliminating the need to rotate and manipulate the fabric during the cutting process.

It incorporates two different pressure systems, one for the X-axis and another for the Y-axis, to keep the fabric stable during the cutting process in both directions.

Built and designed for efficient production of roller blinds, awnings, panels, vertical blinds, Roman shades, mosquito nets, and samples.

- Useful Cutting Width: 3,300 mm

- Standard Useful Cutting Length: 6 or 8,000 mm

- Cutting Tools: Dual Rotary Pressure Blades

- Electrical Consumption, Single Phase: 2.2 kW

- Air Consumption Below 30 l/cycle

- Air Pressure: 6 bar

- Complies with CE Safety Standards

- Automatic cutting of all four sides

- Automatic and tension-free fabric feeding with motorized unwinding device.

- Dynamic "0" point for the start of cutting - the cutting start can be positioned anywhere on the table

- Dual Presser Feet

- Motorized carousel for roll fabric storage under the table **

- Ultrasonics on the side **

- Multi-cut programming

- Athenea software for workflow management, order entry, inventory control, cutting, and welding **

- 7" touchscreen mounted on the bridge

- 21" PC screen on adjacent table

- Software for cutting order management.

- Inventory management software.

- Athenea workflow management software **

- Fabric cutting optimization - using Athenea Workflow Management Software

- Analog pressure adjustment **

- Marker pen with software for Roman blinds **

- Laser projector for fabric alignment **

- Barcode or QR code reader **

- Cross-marking device **

- Label printer **

- Ability to cut from fabric remnants.

- Easy access to the sides of the cutting surface.

- Quiet machine, Silent cutting process: below 50 decibels during cutting time thanks to the special cutting surface and the use of pressure bars instead of the vacuum system.

- Pressure bars to hold the fabric in place in both cutting directions.

- Low power consumption.

- Reduce fabric waste and track the exact amount of wasted fabric thanks to the Athenea optimization and management software.

- Fast cutting and tool movement.

- No need for measurement before or after cutting.

- The machine can extract cutting orders from your ERP system.

- Option to add a motorized storage unit under the table that will link to your inventory.

- Low operating and maintenance costs.

- Low power consumption.

- Cuts: PVC, clear PVC, screen, blackout, acrylic, polyester, coated fabrics, mosquito nets.

- EU Voltage: 220-240V / 50 Hz AC

- USA Voltage: 220-240V / 60 Hz AC

- Air Pressure: 6 bar