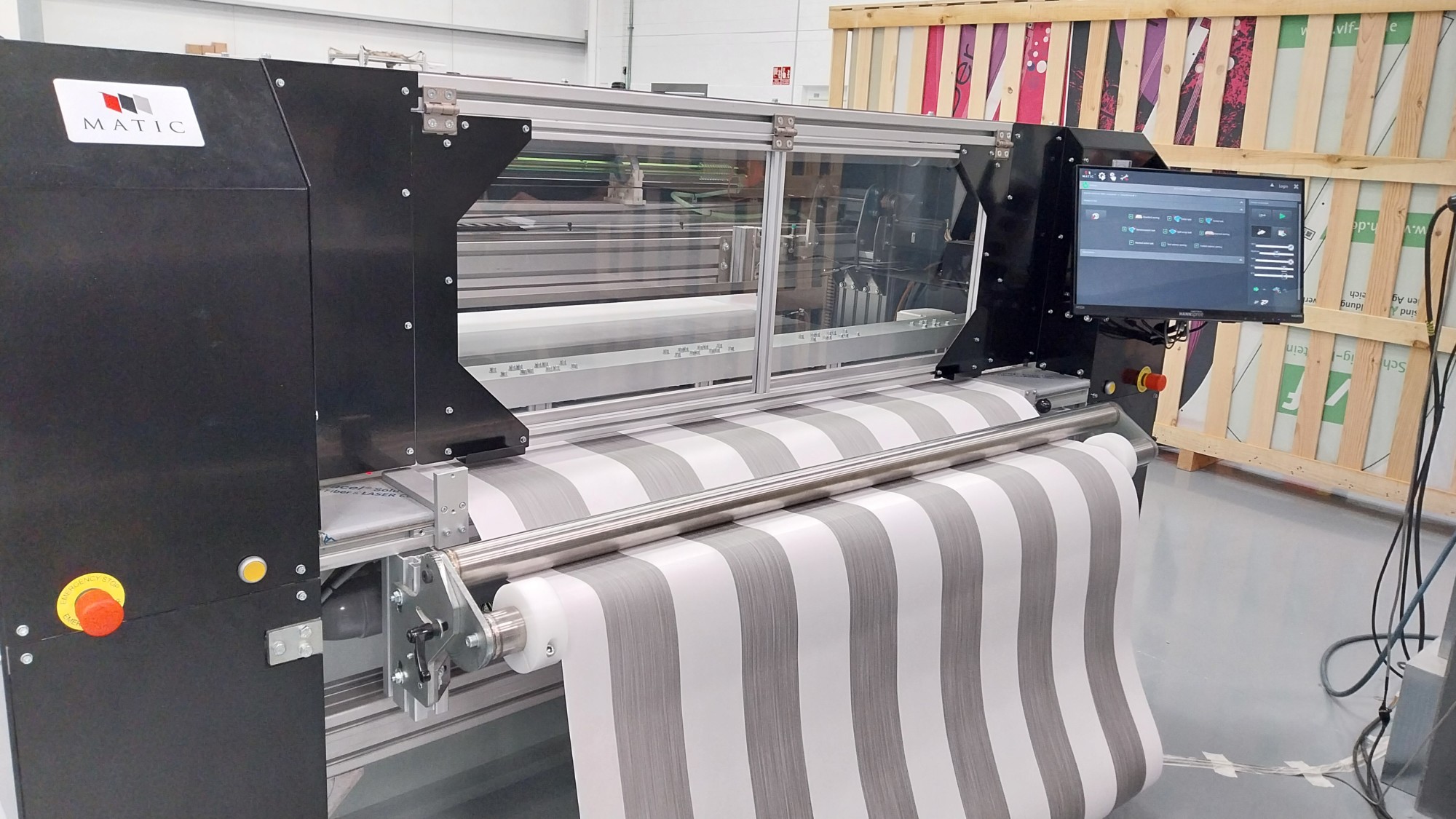

M2 Laser Cutting Machine by Matic

Experience precision and efficiency in modern manufacturing with the M2 Laser Cutting Machine by Matic. Specifically designed for cutting awning fabrics, the M2 Laser offers an unbeatable combination of advanced technology and user-friendly design.

Invest in the M2 Laser Cutting Machine by Matic and elevate your manufacturing processes to a new level. With its combination of innovative technology, user-friendliness, and versatility, the M2 Laser is the perfect partner for anyone looking to maximize their creative potential. Unleash your potential – with Matic!

Invest in the M2 Laser Cutting Machine by Matic and elevate your manufacturing processes to a new level. With its combination of innovative technology, user-friendliness, and versatility, the M2 Laser is the perfect partner for anyone looking to maximize their creative potential. Unleash your potential – with Matic!

- Effective Cutting Length: 5300 mm or 7200mm

- Effective Cutting Width: 1300 mm

- Working Height: 950 mm

- CNC Accuracy: 0.1 mm

- Maximum Speed: 1 m/sec

- Laser: 150 W CO2 – water-cooled

- Power Supply EU: 220-240 V / 50 Hz AC

- Power Supply USA: 220-240 V / 60 Hz AC

- Air Pressure: 6 bar

- Safety Standards: Complies with CE regulations

Key Features:

- Precise Cutting Technology: Thanks to state-of-the-art laser technology, the M2 Laser delivers impressive results even with complex designs and fine details. The cutting accuracy ensures that your projects always meet the highest standards.

- CNC Function for Maximum Efficiency: With the integrated CNC function, you can not only cut the panels of awning fabrics but also the valance simultaneously. This innovative approach saves you the time-consuming step of measuring and cutting the valance, leading to a smooth and efficient production process.

- Cutting Logos or Labels: The M2 Laser can cut logos or labels for LED awnings for your customers. Benefit from the flexibility to create customized products with individual branding and stand out from the competition.

- Versatility: The M2 Laser is ideally suited for cutting materials such as acrylic and polyester fabrics specifically used for awnings. This makes it the perfect solution for companies looking to produce high-quality, customized awning products.

- Precise Measurement of Fabric Width via Sensor: Ensures accurate cutting measurements for your fabric panels.

- Dynamic Zero Point: Optimizes efficiency and accuracy with every cut.

- Athena Software for ERP Integration (optional): Enables seamless integration with your existing systems.

- Intuitive 15-Inch Touchscreen Computer: Provides a user-friendly interface for easy operation.

- Automatic Material Feed After Each Cut: Increases efficiency and reduces manual intervention.

- Automatic Calculation of Cutting Patterns: Saves time and minimizes material waste.

- Remote Maintenance System for Troubleshooting: Ensures quick support and minimal downtime.

- Side Rolling Unit for Cut Fabric Panels (optional): Facilitates handling of finished cuts.

- Horizontal Roll Storage (optional): Saves space and utilizes the area underneath the machine to store fabric.

- Tilt Tray (optional): Efficiently moves rolled fabric to a designated area for the next process.

- No extra steps needed for cutting and measuring the valance: Increases efficiency and reduces time spent.

- More output with the same or fewer employees: Boosts productivity without additional labor costs.

- Daily cost savings in production: Optimizes resource use and lowers operating costs.

- No more manual logo cutting required: Simplifies production and reduces error sources.

- Best cutting quality: Ensures the highest standards in processing and appearance of your products.

ADVANTAGES

- Precise Cutting Technology

- CNC Function for Maximum Efficiency

- Cutting Logos or Labels

- Versatility

Products

CUTTING

Industries

AWNINGS