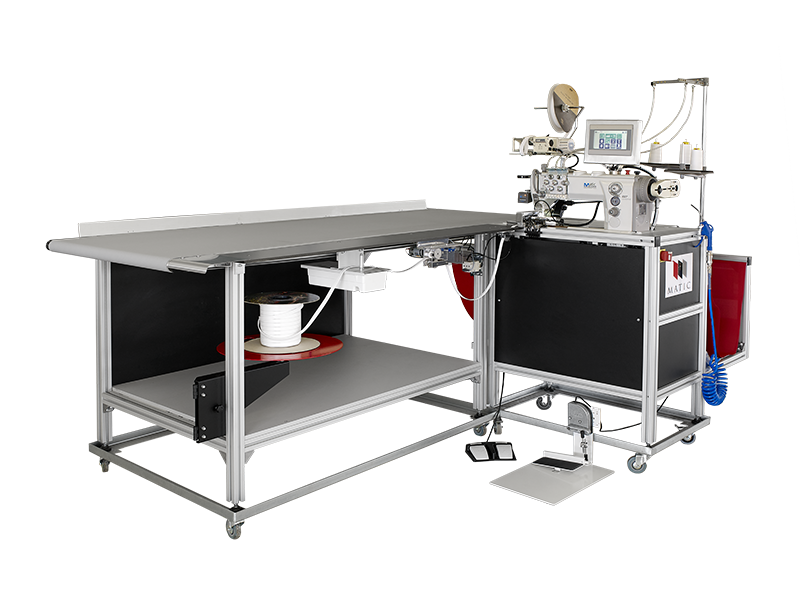

Cronos Basic sewing system is a solution to produce backlits, flags, displays, banners, tents and curtains.

Cronos Basic is a conveyor belt driven automated sewing machine for the application of SEG (keder, spline), pockets, hems, hook and loop fastener and many other sewn applications.

It is the highest quality and most flexible solution for sewing textiles. From a Basic solution, this machine can be built up with various options and attachments, making it perfect for your production and your budget.

Cronos Basic is easy and fast, it will reduce production time, increase your output, and achieve high quality flat seams, without the need of a skilled operator.

The sewing guides will be custom built for your application, making this machine adaptable to your current production style.

Software is installed for remote control and support through an internet connection.

The Industry 4.0 kit is an optional feature that can provide production traceability and data reporting.

It is the highest quality and most flexible solution for sewing textiles. From a Basic solution, this machine can be built up with various options and attachments, making it perfect for your production and your budget.

Cronos Basic is easy and fast, it will reduce production time, increase your output, and achieve high quality flat seams, without the need of a skilled operator.

The sewing guides will be custom built for your application, making this machine adaptable to your current production style.

Software is installed for remote control and support through an internet connection.

The Industry 4.0 kit is an optional feature that can provide production traceability and data reporting.

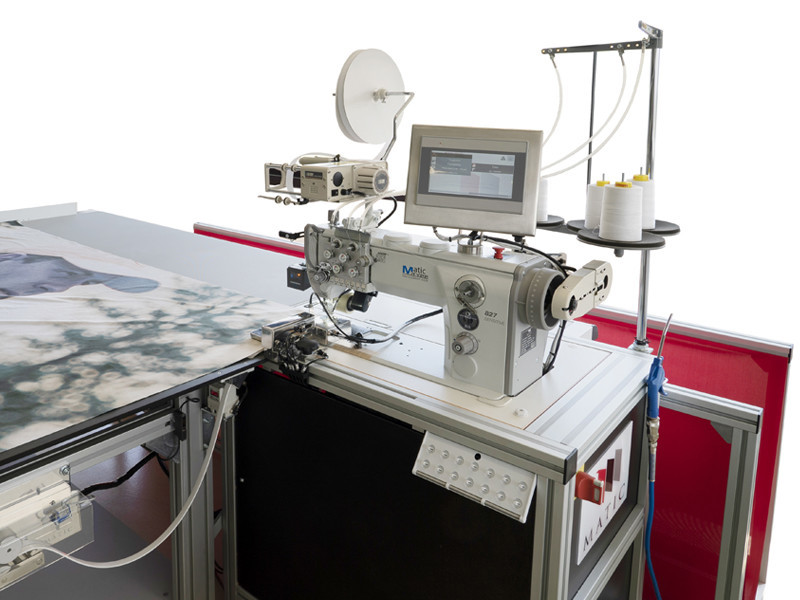

- Double needle sewing head

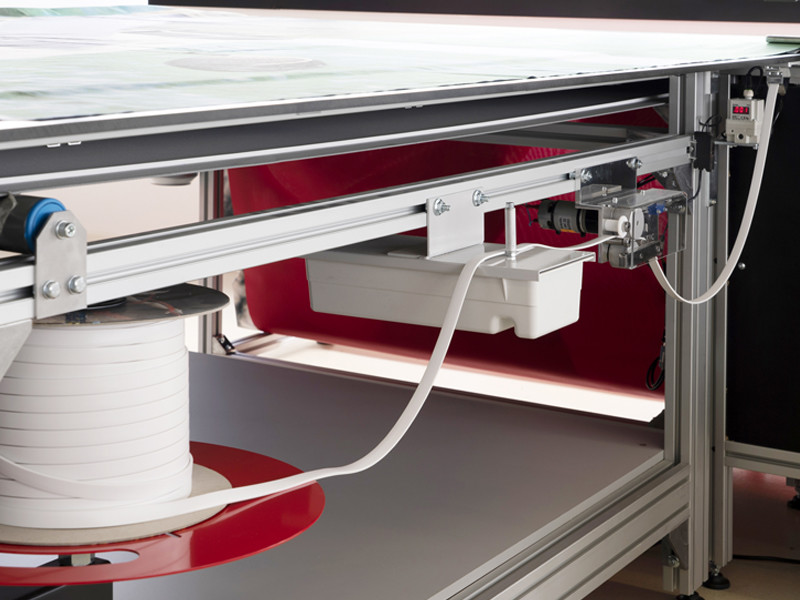

- Conveyorbelt is synchronized with the sewing speed

- Adherent conveyor belt

- Operation modes: manual, semi-automatic and full automatic.

- Machine length 2500mm (98")**

- Machine width 1700mm (67")**

- Machine height 1650mm (65")**

- Weight 150kg (330lbs)**

- Electrical Voltage (EU/US) 220V F+N // 50-60Hz

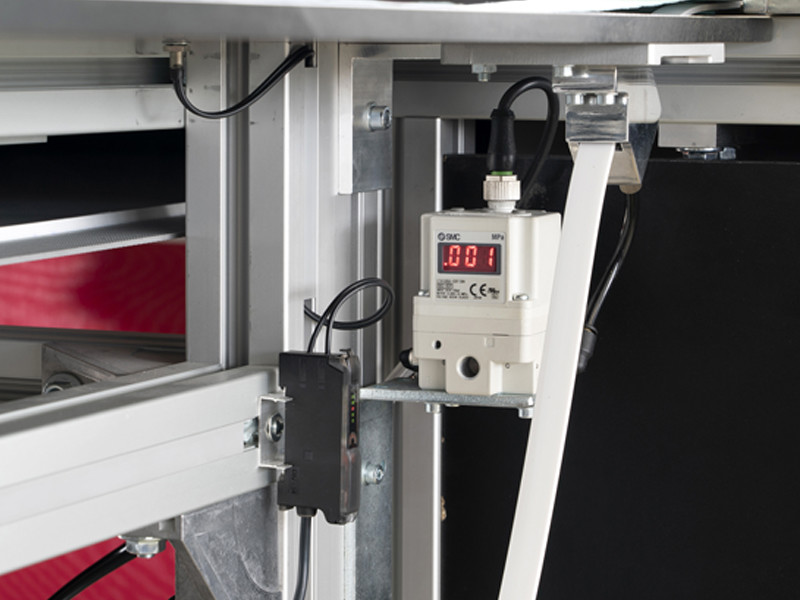

- Air Pressure 5-6 bar

- Complies with CE Safety regulations.

- Fast and easy change of sewing guides - no tools needed.

- Remaining bobbin thread control.

- Automatic return of the fabric.

- Possibility to lock the conveyor belt to facilitate curved seams.

- Rear driven roller - to help guide and track long and heavy fabrics

- Folding side to attach an auxiliary table.

- 7” colour touch screen control panel

- Remote control and support via Wi-Fi or LAN connection

- Bobbin and guide storage

- Drawer under the conveyor belt for easy access to storage

- Production work status - Information on worked hours seen on the touch screen panel.

- Maintenance notice.

- Electronic and programmable tread tension device. *

- Speed reduction sensor*

- Illumination of the sewing area by LED. *

- Additional pedal to move the conveyor belt independently from the sewing head. *

- Tension free feeding of the flat profile (SEG, keder, gasket)*

- Hands-free device.*

- Pneumatic tension meter for flat profile (SEG, keder, gasket)*

- Automatic advancement of the flat profile*

- Puller device*

- Basket to prevent the fabric from touching the floor*

- Needle cooling*

- Hook and Loop Fasterner motorized unwinding system.*

- Industry 4.0 kit*

- Production Traceability and data reporting*

*Optional

- From the basic configuration add any options related to your type of production or for any specific application.

- Guides are custom built for each application - will adapt to your existing production.

- Fabric will return automatically on top of the conveyor belt when sewing reaches the end of the fabric - Faster production, less involvement from the operator.

- The conveyor belt is made of an adherent material to avoid soft fabrics from slipping off, and to be able to pick up heavier fabrics.

- Ergonomic 7” colour touch screen with adjustable positions according to the operator's posture.

- Quick and easy changes of the application modes from the touch screen panel.

- Flag mode - programmable sewing intervals

- Remote control and support via Wi-Fi or LAN connection

ADVANTAGES

- For sewing SEG, flags, displays, banners and more.

- Adherent conveyor belt, returns fabric automatically.

- No skilled seamstress needed.

- 7” colour touch screen control panel.

- Remote control and support.

- Industry 4.0 kit optional.

Products

SEWING

Industries

DIGITAL PRINTING