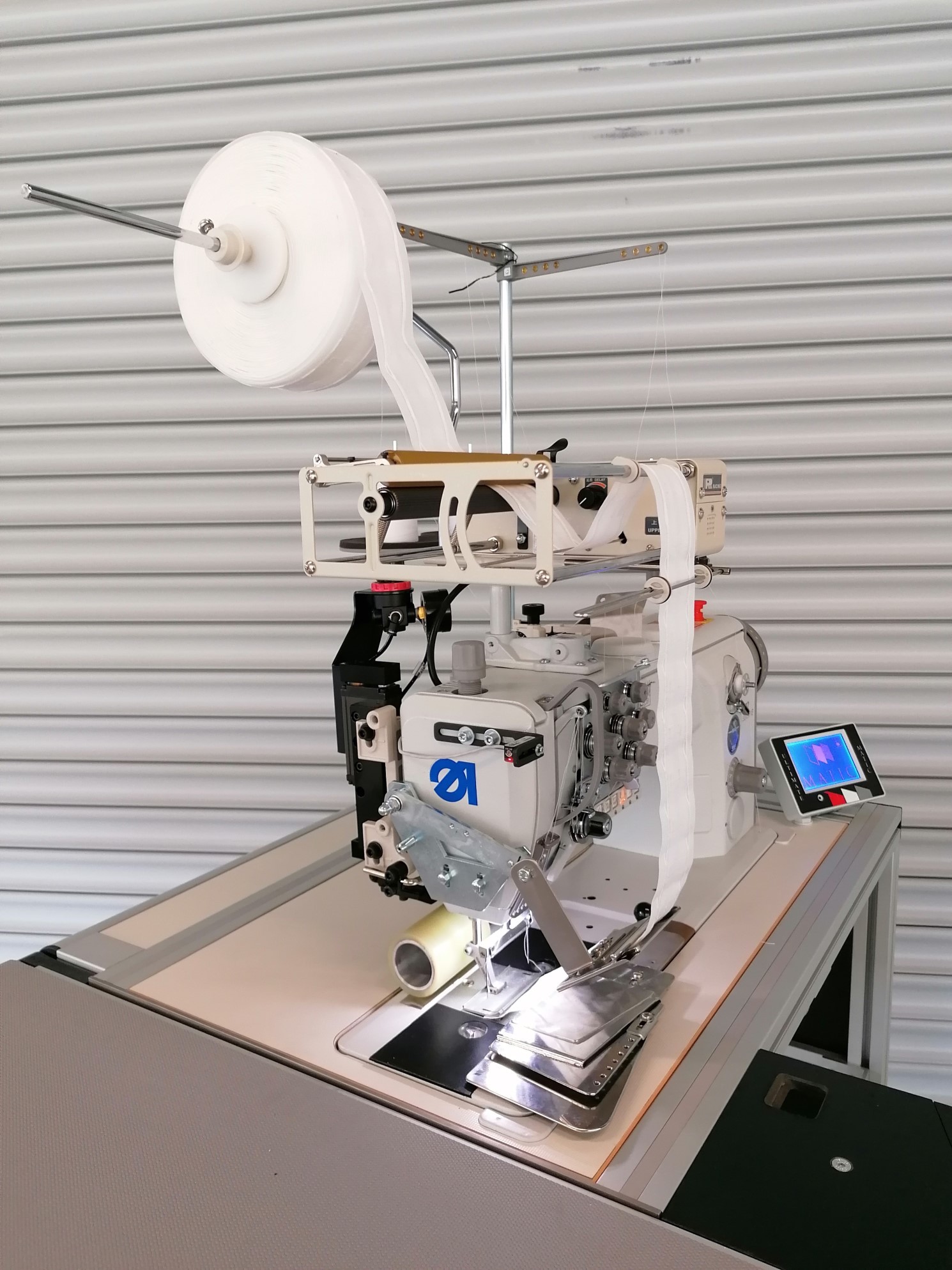

Automatic sewing machine to sew the top tape on curtains. Available with and without conveyor belt.

The Nyx Top Tape machine is a sewing system for finishing the tops of curtains with tape. This machine is available with or without a conveyor belt.

The Nyx Top Tape sewing system is easy and fast, will reduce the manufacture time and will increase the production, with non-skilled operator. The result will be a high quality flat seam.

Now Nyx Family also has the option of Industry 4.0 feature. You can easily achieve production traceability, remote control of operations, and get remote support from Matic.

With Industry 4.0 kit, the sewing program and settings will automatically be loaded by reading the QR code of the work piece.

The Nyx Top Tape sewing system is easy and fast, will reduce the manufacture time and will increase the production, with non-skilled operator. The result will be a high quality flat seam.

Now Nyx Family also has the option of Industry 4.0 feature. You can easily achieve production traceability, remote control of operations, and get remote support from Matic.

With Industry 4.0 kit, the sewing program and settings will automatically be loaded by reading the QR code of the work piece.

- Two needle sewing head, 70 mm needle distance.

- Operation mode: manual, semi-automatic and automatic

- 7" color touch screen control panel

- Electrical voltage (EU/US) 220V F+N // 50-60Hz

- Air pressure 5-6 bar

- Our machine complies with all CE safety rules

- Conveyor belt synchronized with the sewing speed

- Special conveyor belt for curtains

- Conveyor belt length 2380 mm (94")**

- Conveyor belt width 800mm (31")**

- Special needle distance of 70mm, to sew Top Tape in one operation

- Tiltable guide system to ease the operation – no tools required

- Tension-free automatic unwinding device for top tape

- Rear driven roller – to ease the guiding and feeding of heavy fabric

- Led lighting at sewing area

- Touch screen at control panel

- Information of operation status (operation hours) on the touch panel screen

- Maintenance notice

- Remote support via Internet, Wi-Fi or LAN connection

- Industry 4.0 kit*

- QR code reader

- Production Traceability and data reporting

- Additional pedal to use conveyor belt independently from the sewing process

- Automatic return of the sewn material

- Tilt table to adapt with an auxiliary table

- Fabric box

- High productivity and constant quality, thanks to the ergonomic design of the work station for stand up position that helps the operator

- The guides are custom made for each application – will be adapted to the production requirements

- Rear driver roller- to ease the guiding and feeding for flat seams

- Fast and easy change of operation mode at the touch screen control panel.

- Ergonomic 7” colour touch screen with adjustable positions according to the operator's posture.

- Remote access to the software through Wi-Fi or LAN connection, for programming, production data etc.

- Optional Industry 4.0 kit:

QR code also contains information on the program and settings that must be used to sew the application: thread tension etc. - avoiding errors and / or quality problems.

Nyx Top Tape system with conveyor belt

- The conveyor belt synchronizes with the speed of the sewing machine – can be adjusted to light and heavy fabrics

- Automatic return of the fabric on the belt conveyor when the sewing process is finished: faster production, less involvement of the operator

- High productivity and constant flat seam quality with non-skilled operators

- Great solution for a small area. The size of only 4m2, it allows to place it at any location.

Advantages

- 70mm special needle distance.

- Sew the top tape in one operation.

- Tension-free automatic unwinding.

- Rear driver roller - help guide and transport heavy fabrics.

- 7" color touch screen control panel.

- Remote control and support.

- Option of Industry 4.0 kit.

Products

SEWING

Industries

CURTAINS