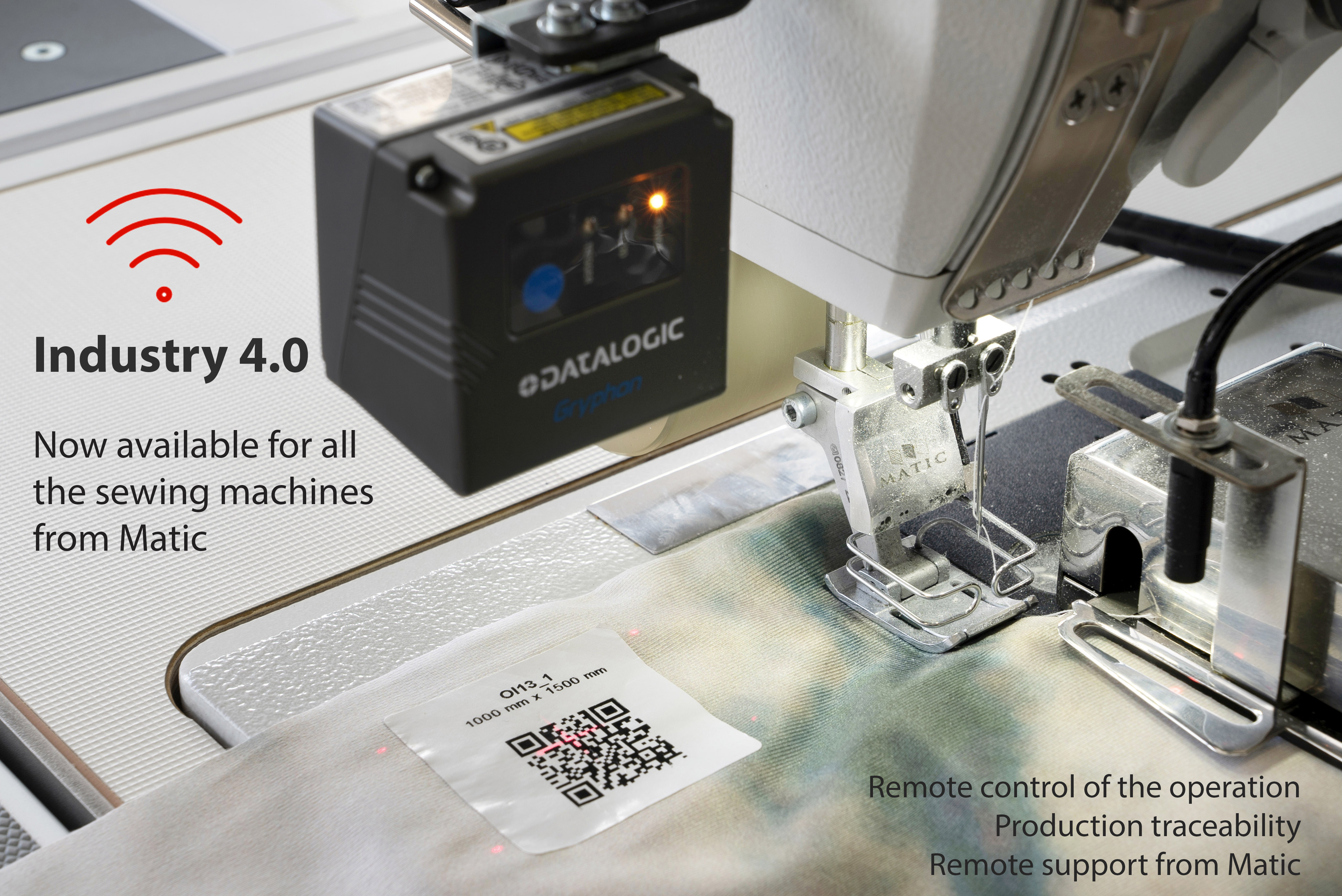

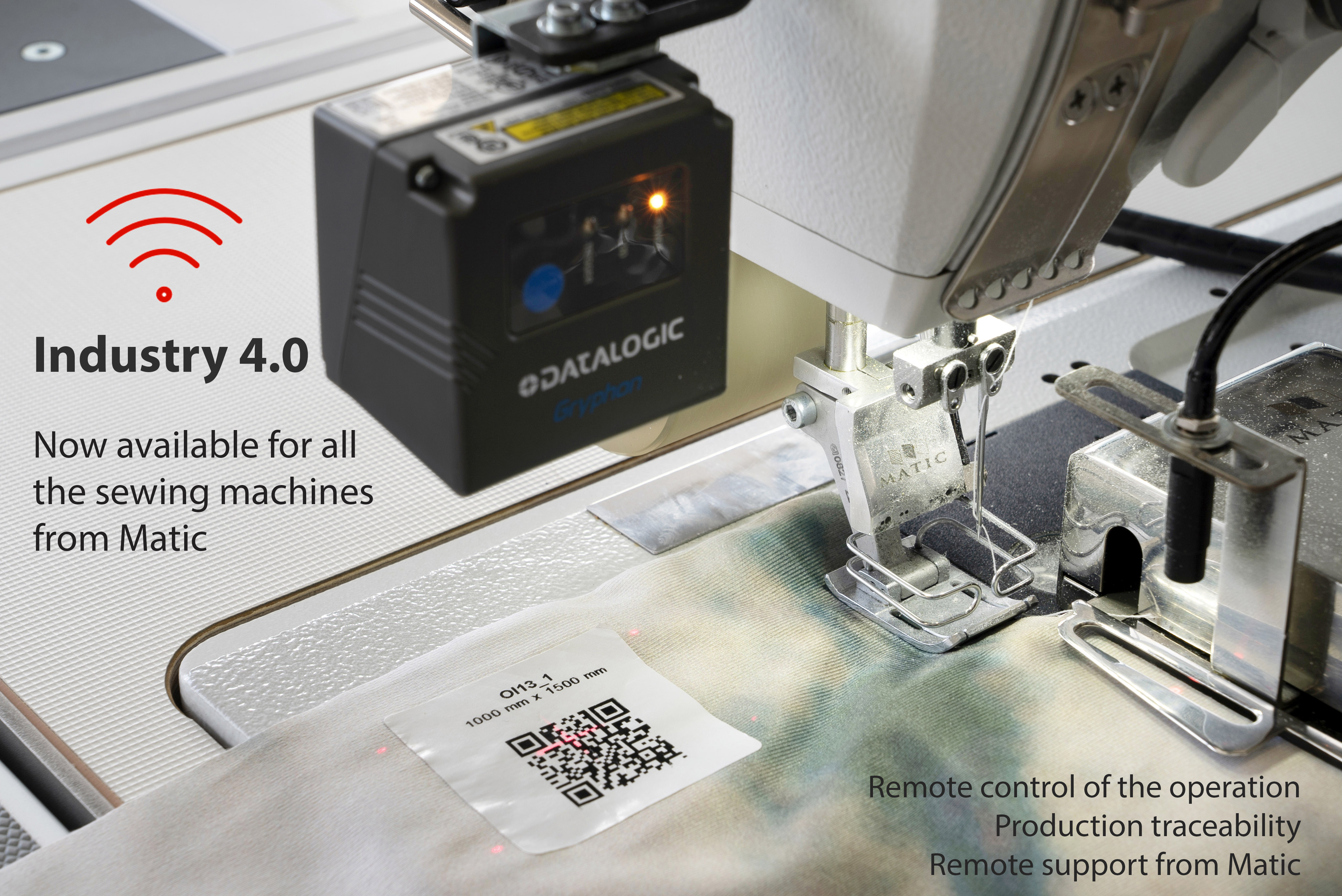

Starting today, our software engineers can install the Industry 4.0 functions on every Matic sewing machine, whether it is a built-in function or as an option.

With Industry 4.0 functions, you can easily achieve production traceability, data reporting, remote control of operations, and get remote technical support from Matic.

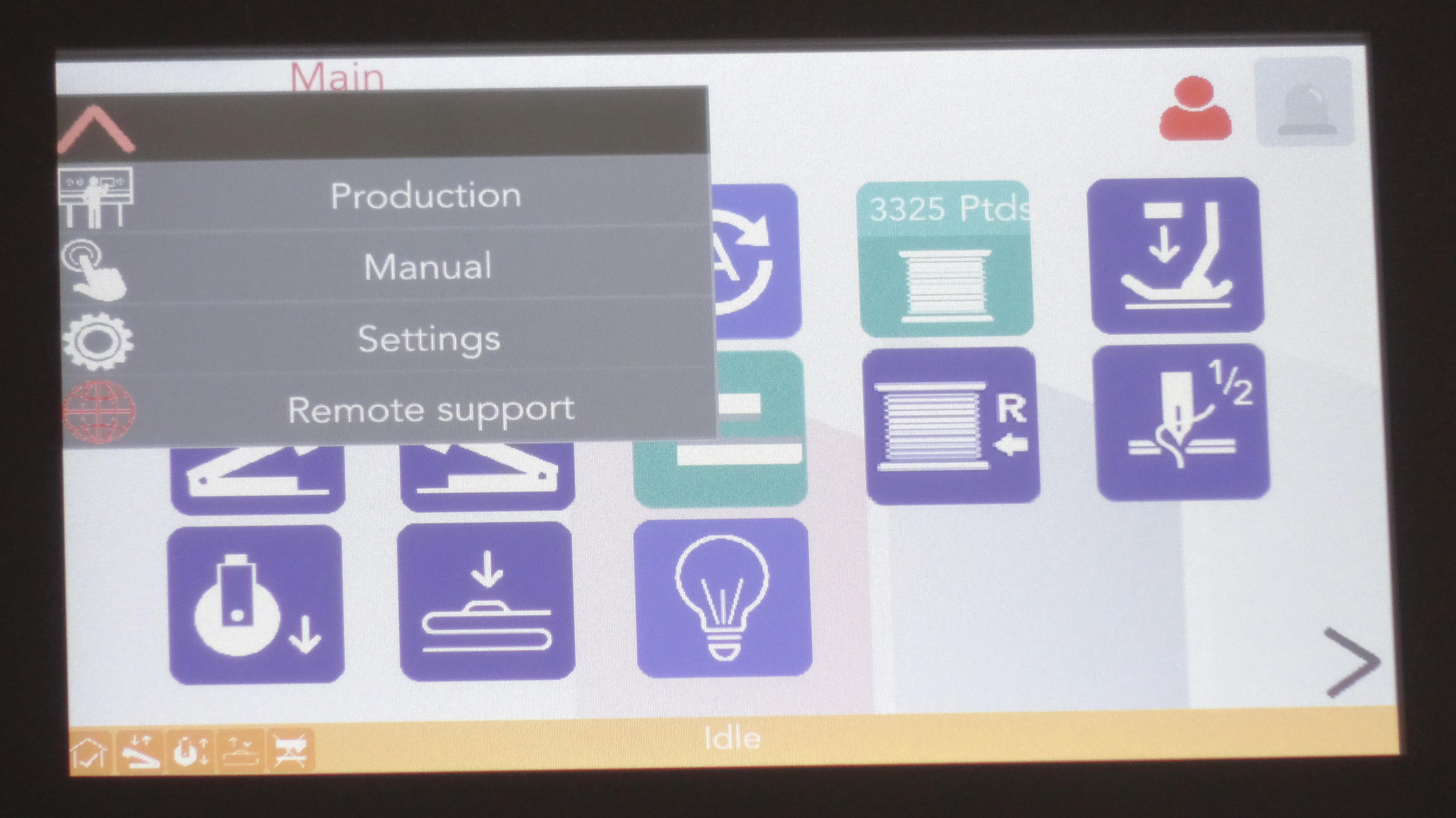

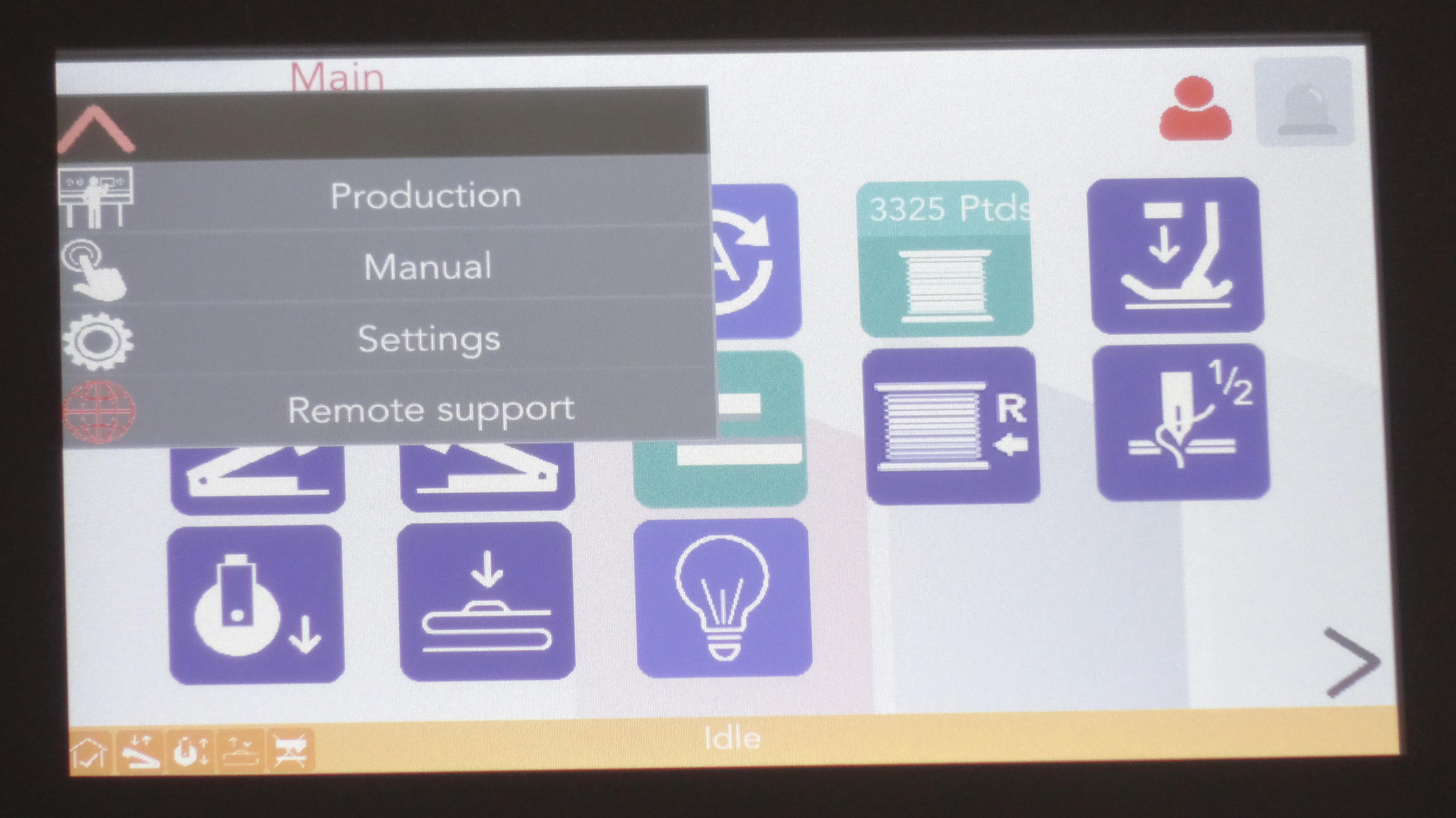

Remote control of operations

Matic machines allow remote access to the machine screen and its manipulation from any computer.

This is how it works:

•Install VNC software in your computer (very easy, and most computers already have it installed)

• Open the program, input the address of your machine, and connect.

• The screens of your machine and computer are now synchronized

• Now you can change the settings, programs, production parameters from your computer.

This system provides great flexibility since it facilitates the view of the machine status, and allows remote interactions with the functions -, be it to consult or update data of the stored programs and groups, the reading of traceability data or the supervision of the production process.

In addition, due to the vast number of devices that have VNC software, you can carry out this operation from either a PC, a tablet or a mobile phone of different operating systems and manufacturers.

Remote support

In the same way, Matic engineers can connect to your machine remotely to resolve software incidents or production incidents. Once the machine has internet access, you can choose whether you authorize access to it by activating or deactivating the function.

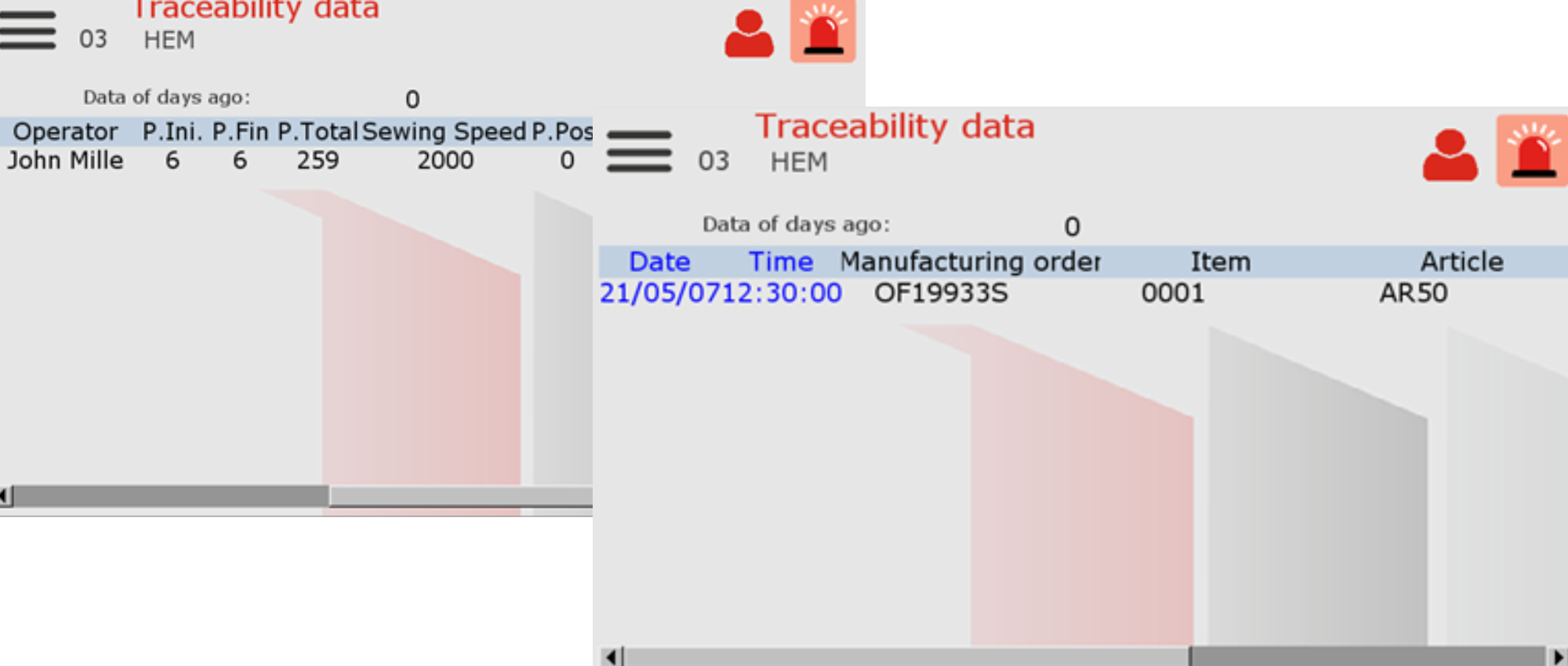

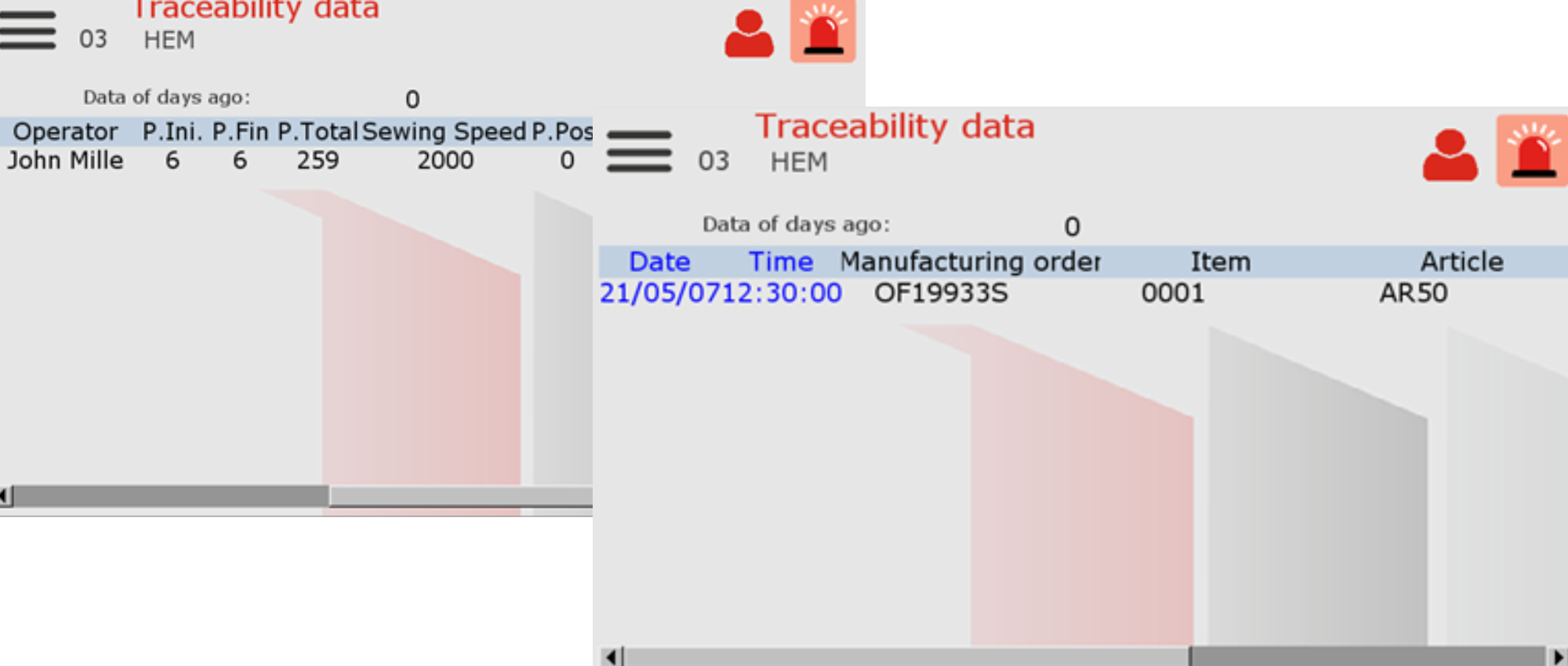

Production traceability

Data and production history (Manufacturing orders, items, articles, operators, programs, etc.) will be recorded in the machine. These data can be exported to Excel for analysis, or you can also import these data to your ERP system.

This is how it works:

• QR code must be generated and printed on a label.

• The labels are fixed to each of the fabric pieces to be sewn.

• Read the QR code before starting the production process.

• When the QR code is read, the machine will load the program indicated. The data for the traceability of the product will be collected by machine, including manufacturing orders, items, articles, operators etc.

You access this information directly on the machine’s screen or by downloading remotely from your PC, tablet, or mobile phone.

QR code contains information on the program and settings that must be used to sew this specific application: thread tension, sewing speed and other parameters. This helps minimize human errors and quality consistency problems.

In addition, now all Matic sewing machines are equipped with ergonomic 7” colour touch screen.

Ergonomic 7” colour touch screen with adjustable position according to the operator's preference. Quick and easy changes of the setting, applications, parameters from the touch screen panel.

Check for more details of the sewing family of Matic

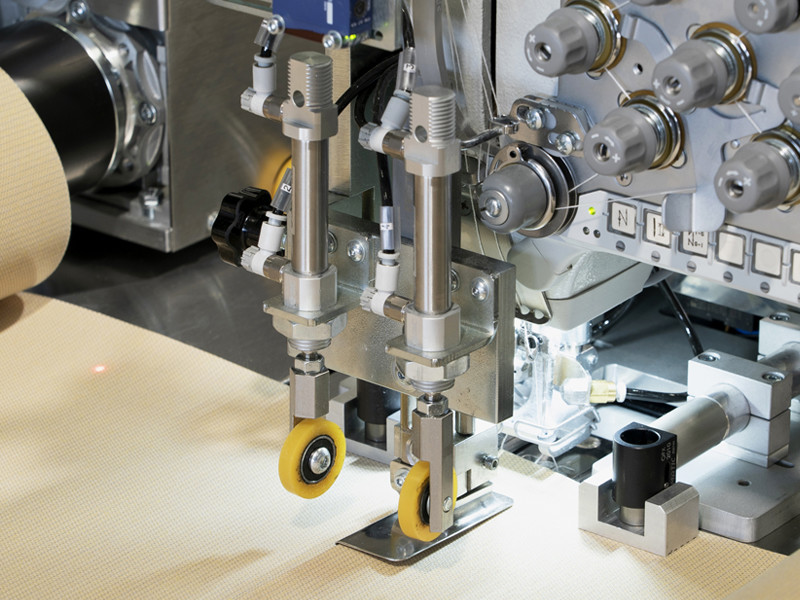

Nyx family: The Nyx family of machines is dedicated for the production of curtains. From the compact version which only occupies 4m², to the fully equipped version with 5-meter conveyor belt, to the options of devices for applying top tape, ripple fold tape etc.

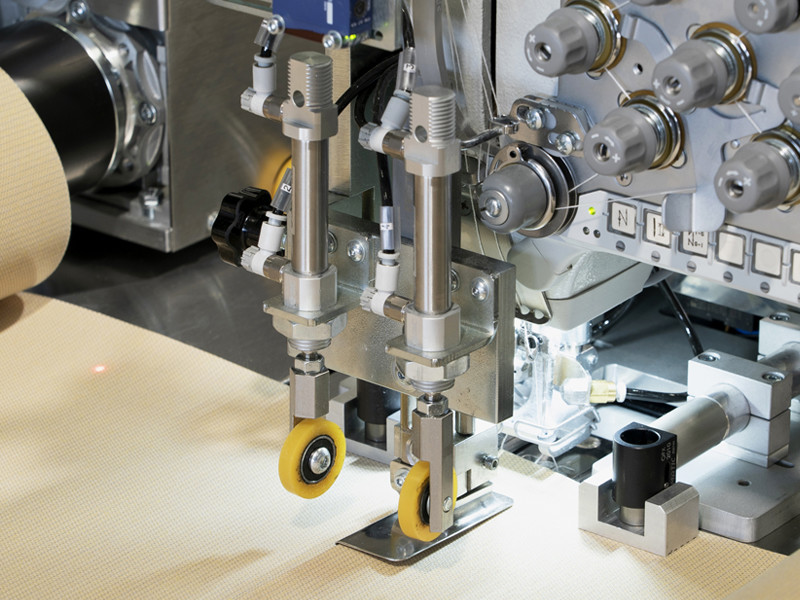

Orion/Hercules: In the Greek mythology, both are giants, famous for their strength. In Matic, Orion and Hercules are designed specifically to sew awnings, that are typically built using heavy fabrics.

strength. In Matic, Orion and Hercules are designed specifically to sew awnings, that are typically built using heavy fabrics.

Cronos family: The Cronos family is created for the finishing production of banners, SEGs, flags in the digital printing industry. Starting with Cronos Go, which is the most economical choice, to the customizable Cronos Basic, to the fully equipped Cronos 4.0 which has industry 4.0 functions built in.

Please contact us for your questions or require a demo.

With Industry 4.0 functions, you can easily achieve production traceability, data reporting, remote control of operations, and get remote technical support from Matic.

Remote control of operations

Matic machines allow remote access to the machine screen and its manipulation from any computer.

This is how it works:

•Install VNC software in your computer (very easy, and most computers already have it installed)

• Open the program, input the address of your machine, and connect.

• The screens of your machine and computer are now synchronized

• Now you can change the settings, programs, production parameters from your computer.

This system provides great flexibility since it facilitates the view of the machine status, and allows remote interactions with the functions -, be it to consult or update data of the stored programs and groups, the reading of traceability data or the supervision of the production process.

In addition, due to the vast number of devices that have VNC software, you can carry out this operation from either a PC, a tablet or a mobile phone of different operating systems and manufacturers.

Remote support

In the same way, Matic engineers can connect to your machine remotely to resolve software incidents or production incidents. Once the machine has internet access, you can choose whether you authorize access to it by activating or deactivating the function.

Production traceability

Data and production history (Manufacturing orders, items, articles, operators, programs, etc.) will be recorded in the machine. These data can be exported to Excel for analysis, or you can also import these data to your ERP system.

This is how it works:

• QR code must be generated and printed on a label.

• The labels are fixed to each of the fabric pieces to be sewn.

• Read the QR code before starting the production process.

• When the QR code is read, the machine will load the program indicated. The data for the traceability of the product will be collected by machine, including manufacturing orders, items, articles, operators etc.

You access this information directly on the machine’s screen or by downloading remotely from your PC, tablet, or mobile phone.

QR code contains information on the program and settings that must be used to sew this specific application: thread tension, sewing speed and other parameters. This helps minimize human errors and quality consistency problems.

In addition, now all Matic sewing machines are equipped with ergonomic 7” colour touch screen.

Ergonomic 7” colour touch screen with adjustable position according to the operator's preference. Quick and easy changes of the setting, applications, parameters from the touch screen panel.

Check for more details of the sewing family of Matic

Nyx family: The Nyx family of machines is dedicated for the production of curtains. From the compact version which only occupies 4m², to the fully equipped version with 5-meter conveyor belt, to the options of devices for applying top tape, ripple fold tape etc.

Orion/Hercules: In the Greek mythology, both are giants, famous for their

strength. In Matic, Orion and Hercules are designed specifically to sew awnings, that are typically built using heavy fabrics.

strength. In Matic, Orion and Hercules are designed specifically to sew awnings, that are typically built using heavy fabrics.Cronos family: The Cronos family is created for the finishing production of banners, SEGs, flags in the digital printing industry. Starting with Cronos Go, which is the most economical choice, to the customizable Cronos Basic, to the fully equipped Cronos 4.0 which has industry 4.0 functions built in.

Please contact us for your questions or require a demo.