In the first post of this blog series, we talked about how we apply the “less is more” concept in designing and manufacturing the new PERSEO welder, to help our customers to deal with the issues faced by most companies lately: shortage of skilled labour, limited production space, delayed delivery time, etc.

In this second post we will talk about how our cutting machines can help customers achieve MORE productivity by having LESS of the troubles mentioned above.

M1 is a line of automatic XY cutting machines designed to cut a wide variety of technical textiles: PVC, screen, clear PVC, black-out, zebra shade fabrics, mosquito nets, etc. Built and designed for the efficient production of roller blinds, roller shades, vertical blinds, roman shades, exterior screens, mosquito nets and samples.

When paired with Matic’s Athenea Software for fabric optimization (nesting), the “less is more” concept in our cutting machines will bring your production the following benefits:

Less waste of fabric

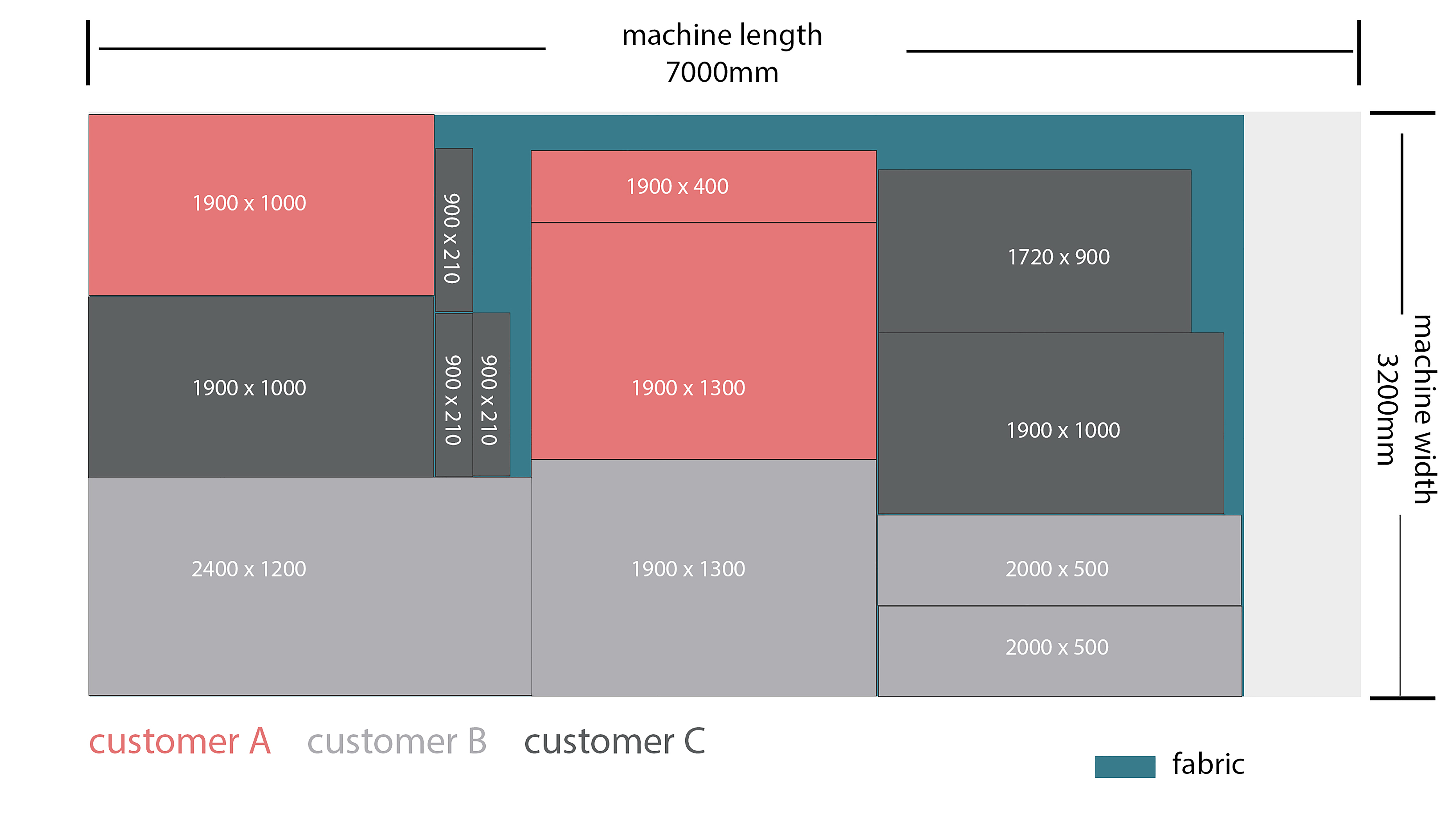

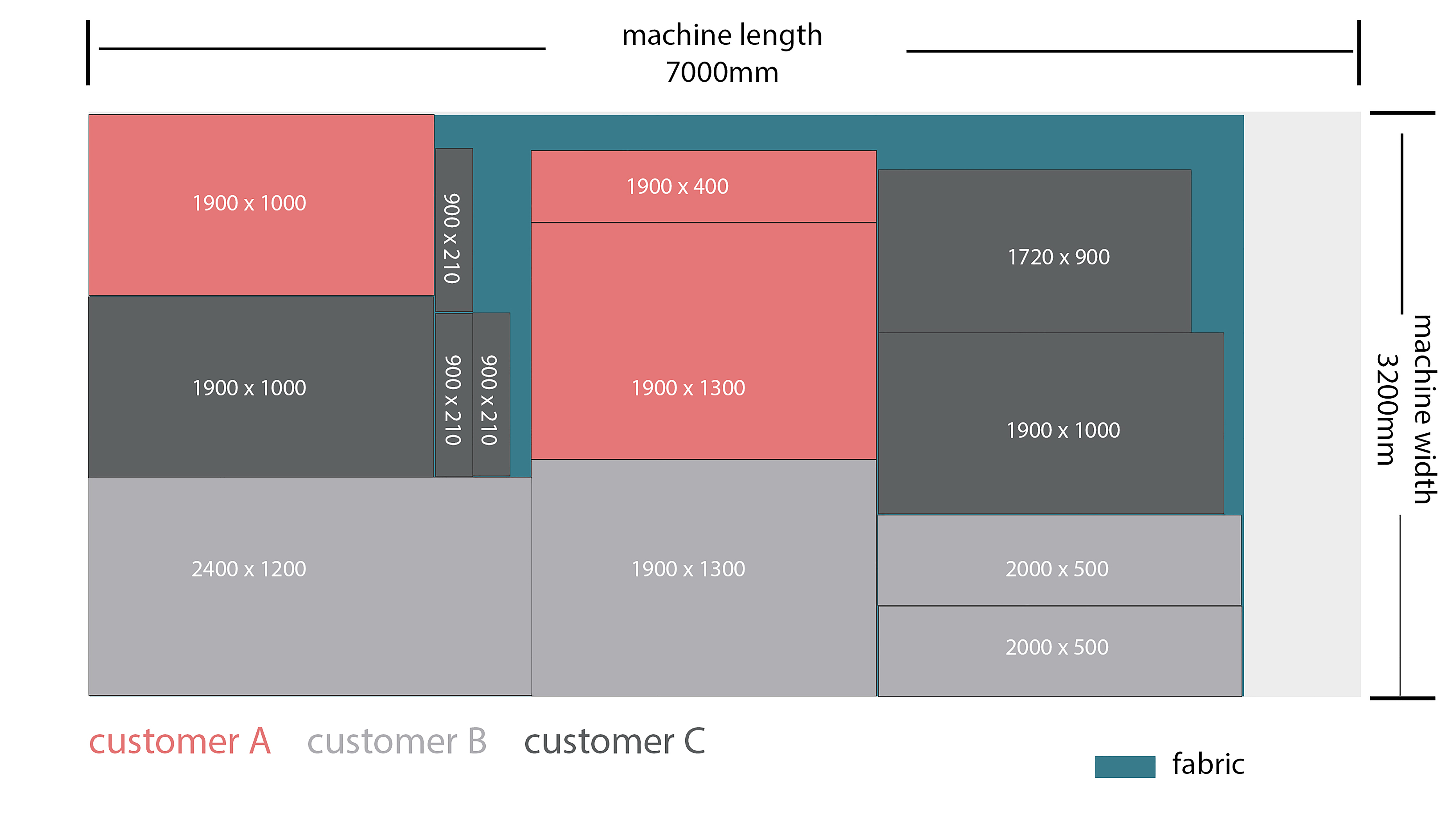

As shown in the figure below, Athenea can group orders from different job orders which require the same fabric, even if the job orders are from different customers, and then automatically calculate and create the cutting profile to make most use of the fabric. In this way, fabric waste will be reduced. In this example, the fabric usage is 91%, so the calculated waste is 9%.

According to the feedback from our customers, on average 15-30% of fabric saving can be achieved with the M1 cutting table paired with Athenea Software.

This helps our customers reduce their ecological footprint as well – an issue that no one can ignore nowadays.

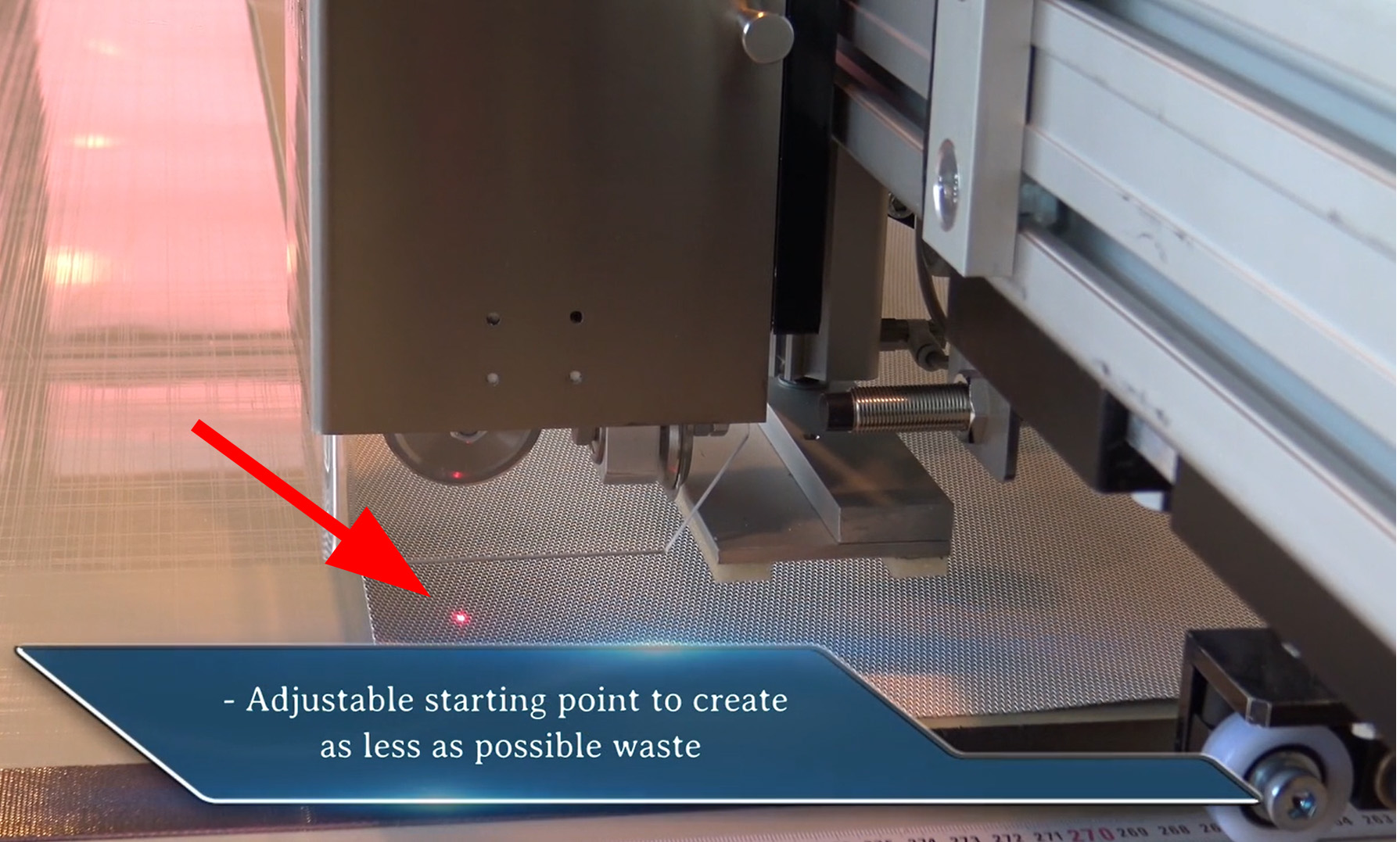

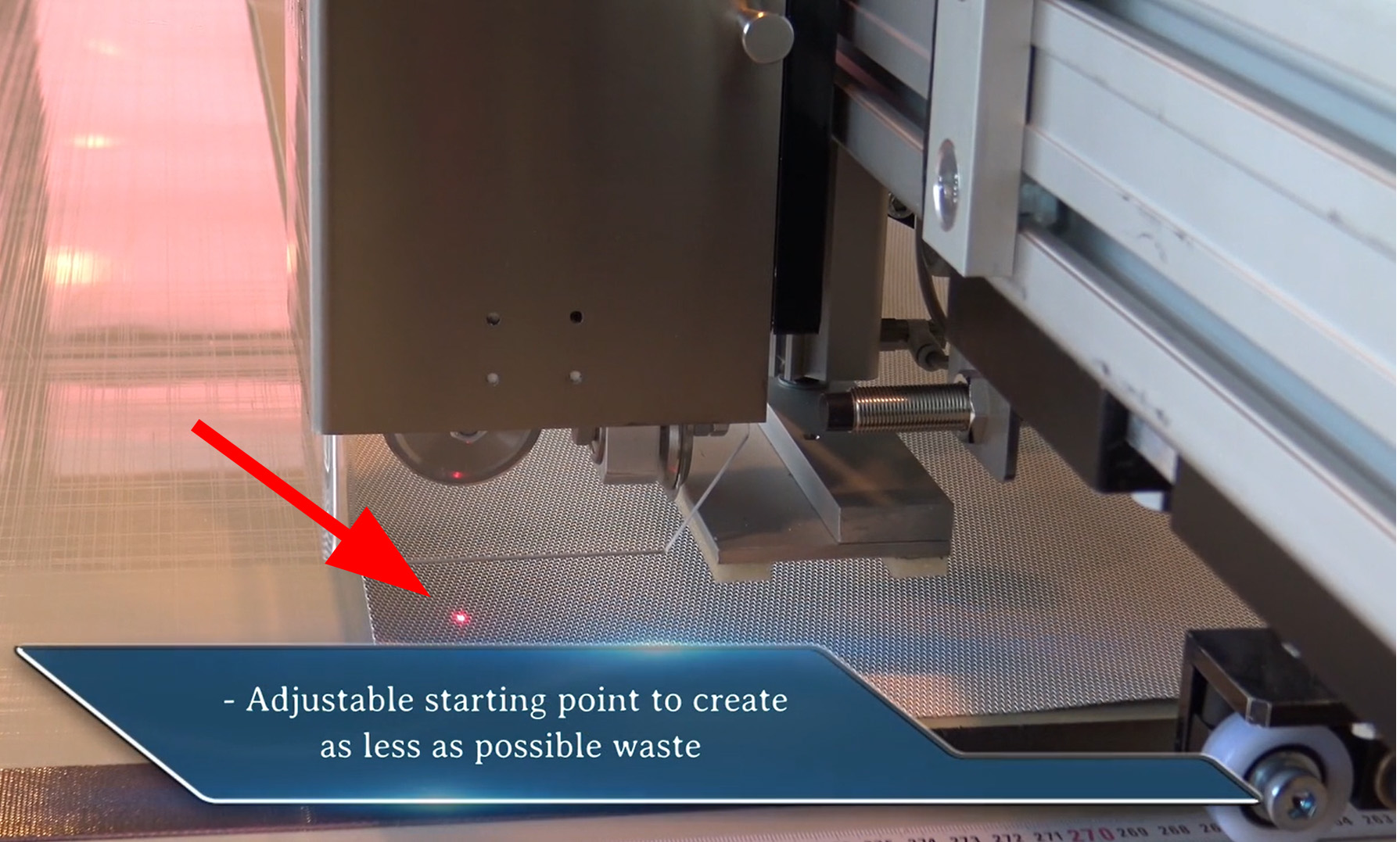

To minimize the fabric waste, we further developed a Software feature called - M1 Defect Detection. When the operator sees the defect on the fabric, they can pinpoint the location of the defect with the laser of M1. This information will be passed to Athenea which will adjust the cutting file with just-in-time nesting, the cutting tool will therefore bypass the defect while making most use of the fabric.

M1 Defect Detection. When the operator sees the defect on the fabric, they can pinpoint the location of the defect with the laser of M1. This information will be passed to Athenea which will adjust the cutting file with just-in-time nesting, the cutting tool will therefore bypass the defect while making most use of the fabric.

Less operators are needed

When you cut manually or do linear cutting, due to the big size of some blinds, you need two operators to cooperate. With XY cutting, you will save time in handling of the fabric. In addition, since Athenea will take orders from your ERP system, group orders, calculate and create the cutting profile automatically, you will save a lot of time thinking on how to cut to save fabric. With all the time saved, you can produce more without needing more operators.

Less errors

With Athenea connecting with your ERP system and making automatic cut file calculations, you will avoid the possible human errors that can occur when inputting data manually and relying on human skills for calculations etc.

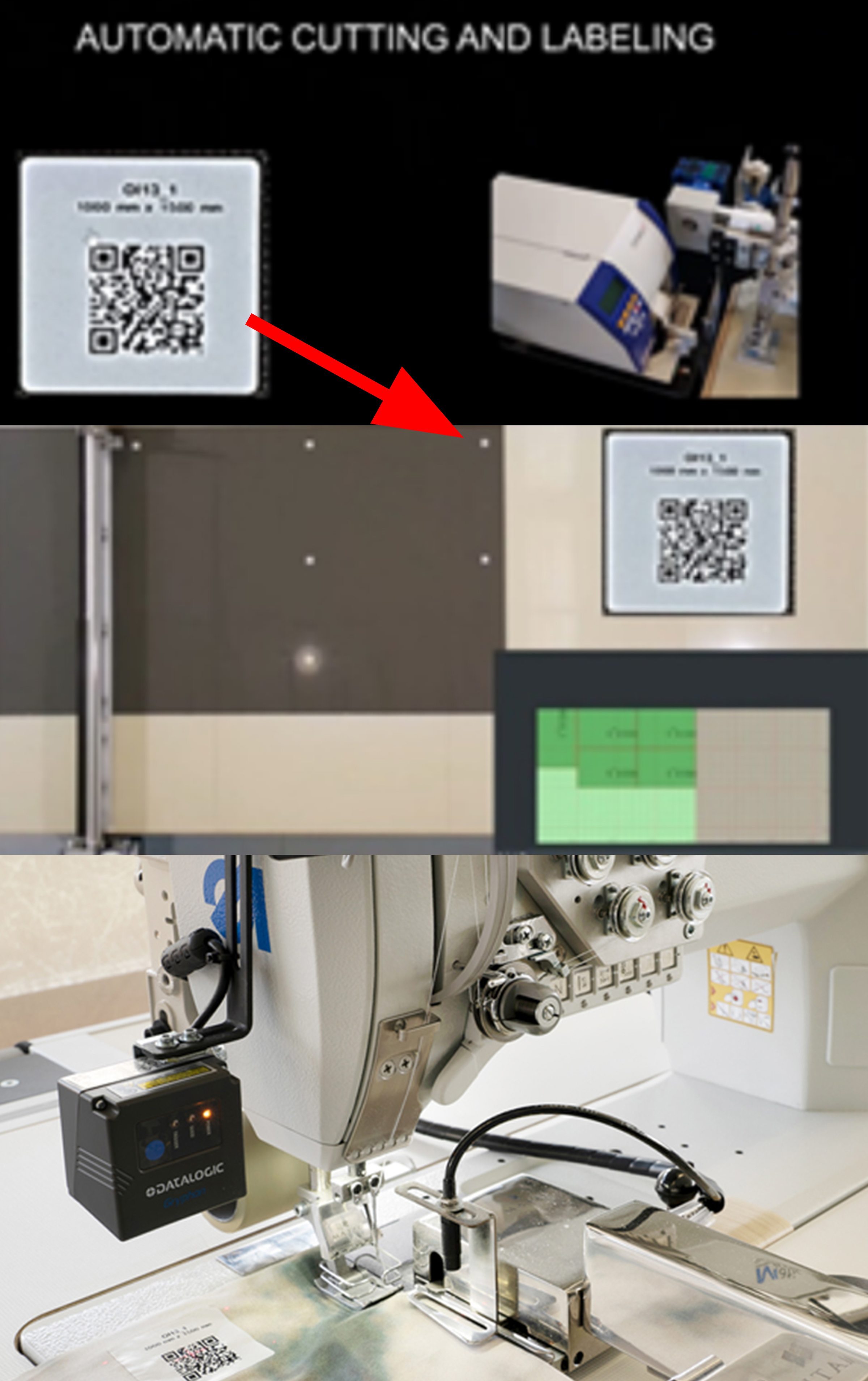

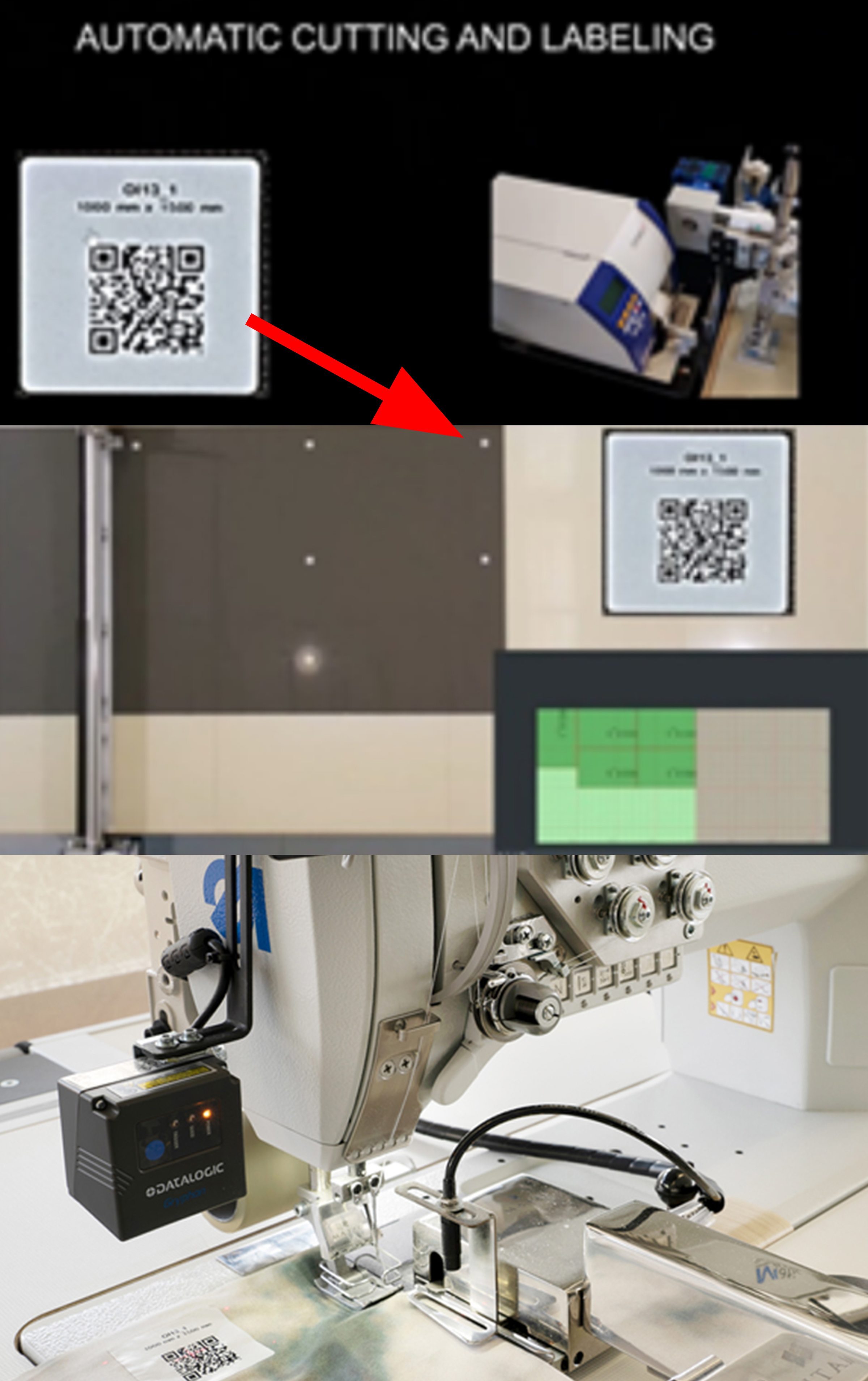

In addition, an optional label printer can be added to the cutting machine. It can print and stick QR labels on each individual cut on the table. Every piece of cut fabric will then carry all the information related to that particular job, and it will be passed to the next step in your production process: welding or sewing. Again, human errors will be avoided.

While we focus on the “less” part of our “less is more” concept, all our innovations are aimed at one goal: for our customers to gain “more” productivity.

If you find that these innovations are helpful and want to know more, click here: M1 PC and M1 ULTIMATE

Or contact us for all your questions.

Stay tuned for the next post of ¨LESS IS MORE¨ blog series.

The last post: LESS IS MORE (1)

In this second post we will talk about how our cutting machines can help customers achieve MORE productivity by having LESS of the troubles mentioned above.

M1 is a line of automatic XY cutting machines designed to cut a wide variety of technical textiles: PVC, screen, clear PVC, black-out, zebra shade fabrics, mosquito nets, etc. Built and designed for the efficient production of roller blinds, roller shades, vertical blinds, roman shades, exterior screens, mosquito nets and samples.

When paired with Matic’s Athenea Software for fabric optimization (nesting), the “less is more” concept in our cutting machines will bring your production the following benefits:

Less waste of fabric

As shown in the figure below, Athenea can group orders from different job orders which require the same fabric, even if the job orders are from different customers, and then automatically calculate and create the cutting profile to make most use of the fabric. In this way, fabric waste will be reduced. In this example, the fabric usage is 91%, so the calculated waste is 9%.

According to the feedback from our customers, on average 15-30% of fabric saving can be achieved with the M1 cutting table paired with Athenea Software.

This helps our customers reduce their ecological footprint as well – an issue that no one can ignore nowadays.

To minimize the fabric waste, we further developed a Software feature called -

M1 Defect Detection. When the operator sees the defect on the fabric, they can pinpoint the location of the defect with the laser of M1. This information will be passed to Athenea which will adjust the cutting file with just-in-time nesting, the cutting tool will therefore bypass the defect while making most use of the fabric.

M1 Defect Detection. When the operator sees the defect on the fabric, they can pinpoint the location of the defect with the laser of M1. This information will be passed to Athenea which will adjust the cutting file with just-in-time nesting, the cutting tool will therefore bypass the defect while making most use of the fabric.Less operators are needed

When you cut manually or do linear cutting, due to the big size of some blinds, you need two operators to cooperate. With XY cutting, you will save time in handling of the fabric. In addition, since Athenea will take orders from your ERP system, group orders, calculate and create the cutting profile automatically, you will save a lot of time thinking on how to cut to save fabric. With all the time saved, you can produce more without needing more operators.

Less errors

With Athenea connecting with your ERP system and making automatic cut file calculations, you will avoid the possible human errors that can occur when inputting data manually and relying on human skills for calculations etc.

In addition, an optional label printer can be added to the cutting machine. It can print and stick QR labels on each individual cut on the table. Every piece of cut fabric will then carry all the information related to that particular job, and it will be passed to the next step in your production process: welding or sewing. Again, human errors will be avoided.

While we focus on the “less” part of our “less is more” concept, all our innovations are aimed at one goal: for our customers to gain “more” productivity.

If you find that these innovations are helpful and want to know more, click here: M1 PC and M1 ULTIMATE

Or contact us for all your questions.

Stay tuned for the next post of ¨LESS IS MORE¨ blog series.

The last post: LESS IS MORE (1)